6-Axis vs. 5-Axis Swiss-Type Lathes: The Revolution in Precision Machining Brought by an Extra Axis

6-Axis vs. 5-Axis Swiss-Type Lathes: The Revolution in Precision Machining Brought by an Extra Axis

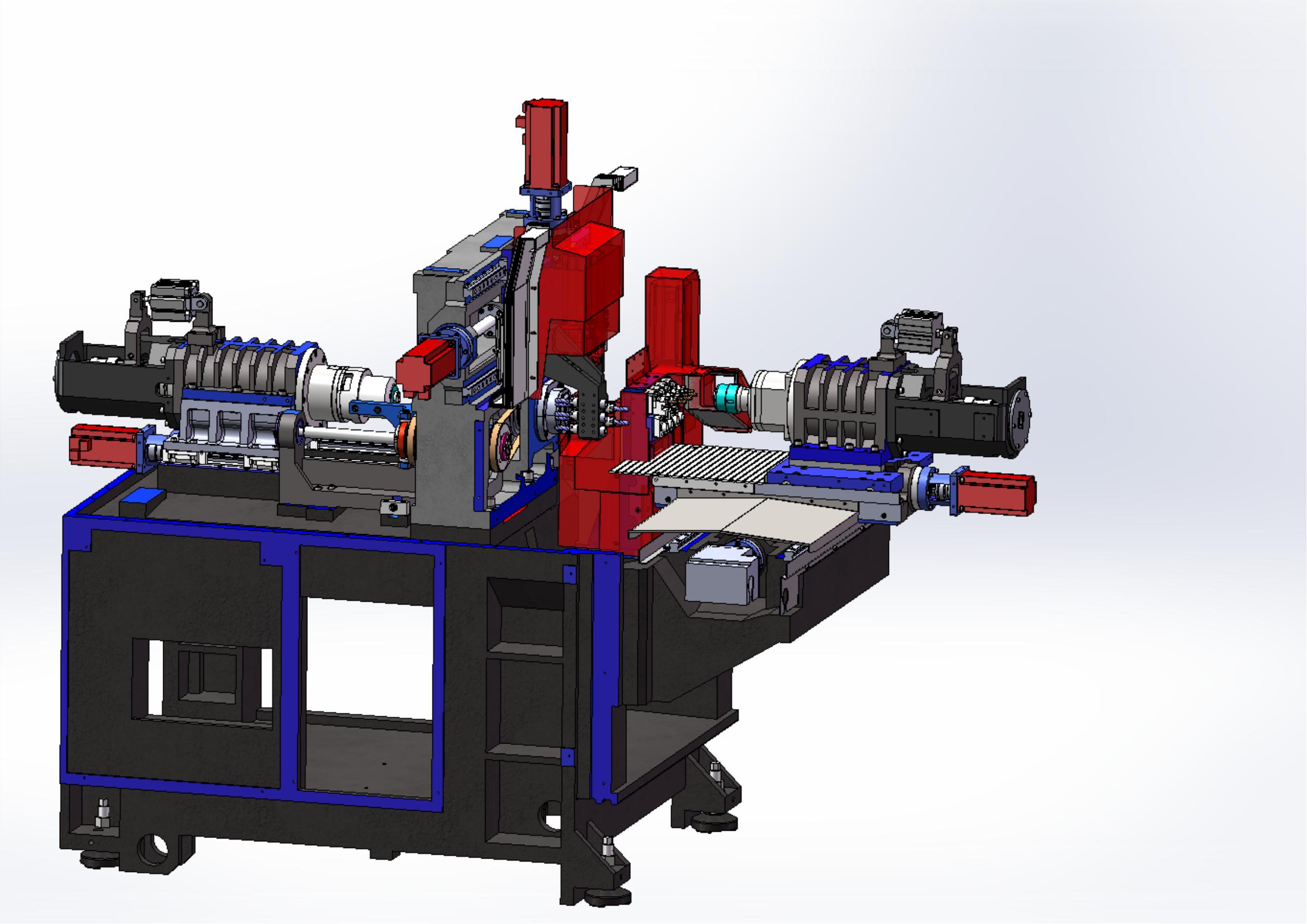

——How the Tk SA-266 6-Axis Swiss-Type Lathe Redefines the Manufacturing of Complex Parts

I. What Exactly is the “Sixth Axis” of a 6-Axis Swiss-Type Lathe?

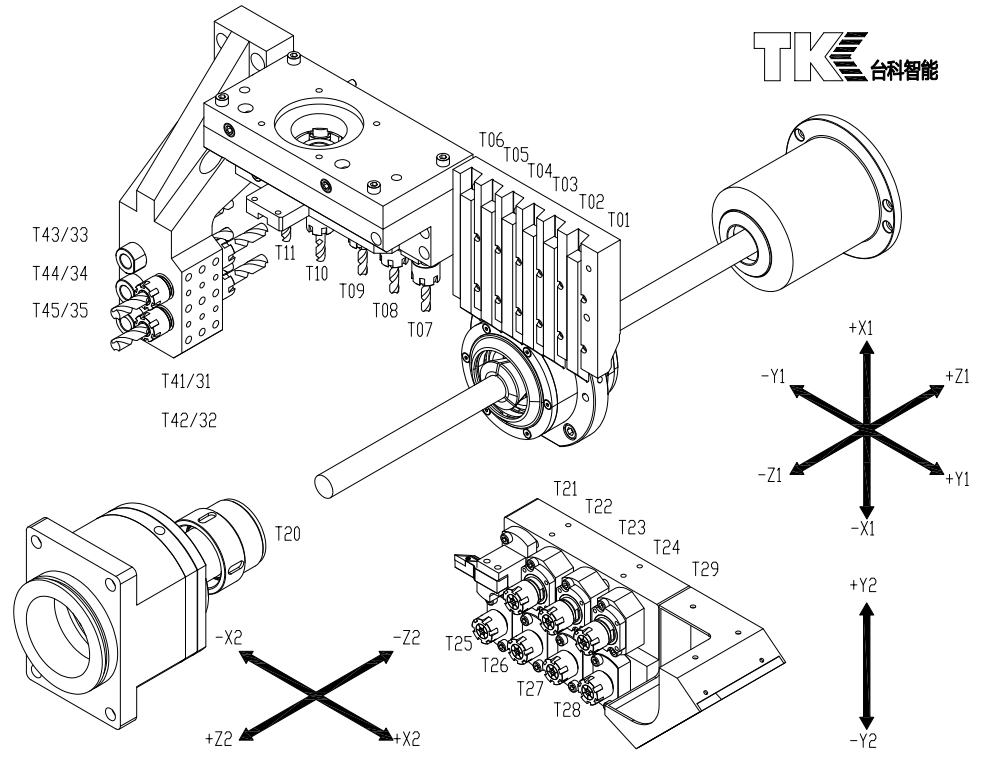

A traditional 5-axis Swiss-type lathe typically refers to the five-axis simultaneous movement of X1/Y1/Z1 (main spindle area) + C1 (rotation of the main spindle) + B (tool swing). In contrast, a 6-axis Swiss-type lathe expands the number of axes in two ways:

Y2 axis (Y axis of the sub-spindle): For example, with the dual-Y axis design of the Tk SA-266, the sub-spindle has an additional independent Y-axis movement.

Second powered rotary tool: In some models, a powered tool with a Y2 axis is added on the side of the sub-spindle.

Synchronous Machining with Dual Y Axes (Taking the Taike 266 as an Example)

Y1 axis of the main spindle: Supports lateral machining such as eccentric hole drilling and side milling.

Y2 axis of the sub-spindle: Enables independent machining of eccentric features at the rear end.

Application case:

When machining an automotive turbocharger shaft, the Y1 axis of the main spindle mills the front inclined surface, and the Y2 axis of the sub-spindle simultaneously drills the eccentric oil hole at the rear end, increasing the machining efficiency by 40%.

Technical Advantages:

The main and sub-spindles can perform turning/milling simultaneously. For example, while the main spindle machines the outer diameter, the sub-spindle mills the keyway synchronously.

I. Axis Configuration and Machining Capability

Increase in the number of axes: The 6-axis Swiss-type lathe adds the Y2 axis function on the basis of the 5-axis configuration, such as adding a rear powered head or enabling movement in more dimensions. This makes the axis configuration of the 6-axis Swiss-type lathe more advanced, providing more possibilities for complex machining.

Enhancement of machining dimensions: Due to the increase in the number of axes, the 6-axis Swiss-type lathe can complete more complex and precise machining tasks. It can finish a variety of compound processes, including turning, drilling, boring, tapping, and engraving, all at once, greatly improving both machining efficiency and quality.

III. Tool Configuration and Machining Flexibility

Richness of tools: The 6-axis Swiss-type lathe can usually be equipped with a wider variety of tools to meet the requirements of different machining tasks. This gives the 6-axis Swiss-type lathe higher flexibility and adaptability during the machining process.

Expansion of the machining range: Thanks to the richness of tool configuration and the increase in the number of axes, the 6-axis Swiss-type lathe can machine a wider variety of complex workpieces, such as components with complex curved surfaces. This further expands its machining range and application areas.

IV. Machining Precision and Stability

High-precision machining: During the cutting process of the 6-axis Swiss-type lathe, the material always remains in a fixed position, endowing it with excellent rigidity and high-precision machining capabilities. Such high-precision machining capabilities are particularly crucial for industries with high-precision requirements, such as aerospace and medical devices.

Enhanced stability: The design of the 6-axis Swiss-type lathe is usually more advanced, with higher bed strength and rigidity, better spindle performance, and a more precise feeding system. These features make the 6-axis Swiss-type lathe more stable during the machining process and enable it to maintain a high-precision machining state for an extended period.

V. Price and Application Areas

Higher price: Due to its higher technical level and configuration, the price of a 6-axis Swiss-type lathe is usually higher than that of a 5-axis Swiss-type lathe. However, considering its higher machining precision, flexibility, and efficiency, this price difference is reasonable.

Wide application areas: The 6-axis Swiss-type lathe is suitable for manufacturing highly complex and precise components and is widely used in industries with high-precision requirements, such as aerospace, automotive manufacturing, and medical devices. These industries have extremely high requirements for machining precision and efficiency, and the 6-axis Swiss-type lathe is the ideal choice to meet these needs.