6-axis siwss machine vs 5-axis swiss machine

How to choose equipment based on part complexity?

——From automotive parts to aerospace, the scene boundary of axis expansion

Ⅰ-Core difference: The machining dimension defined by the number of axes

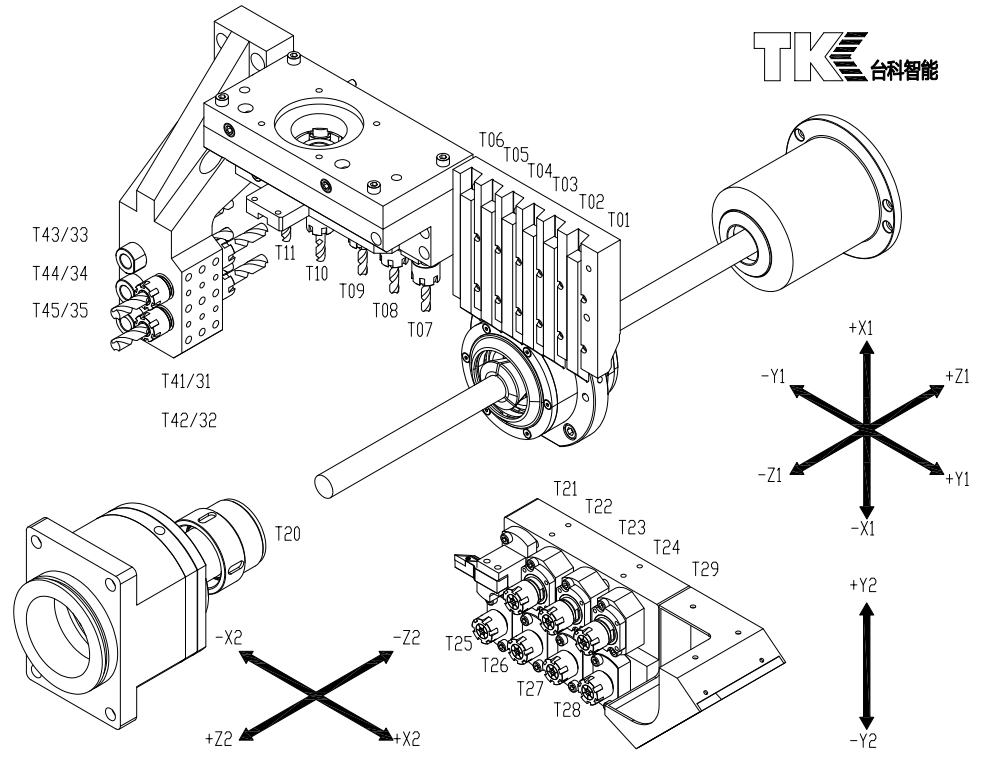

5-axis swiss machines are usually X1/Y1/Z1 (main machining area)+C1 (spindle rotation)+B (tool swing), supporting 3D surface machining;

The 6-axis swiss machine adopts dual Y-axis (Y1 main shaft+Y2 auxiliary shaft) or second turret, adding fourth dimension control to achieve independent Y-axis movement of dual stations.

Ⅱ- Typical application scenarios of 5-axis swiss lathe machine

1. Medium complexity shaft components

Case: Automotive transmission shaft, hydraulic piston rod

Processing requirements:

One time processing of end face/outer circle/inner hole

Single Y-axis completion of * * ± 15mm eccentric hole * * (e.g. eccentricity ≤ 2mm for a 10mm hole)

Advantages:

20% -30% lower cost than 6-axis, suitable for scenarios with batch stability and accuracy requirements of ≤± 5 μ m.

2. Symmetrical parts that require backside processing

Case: Motor rotor, coupling

Processing technology:

Main spindle outer circle → Auxiliary spindle clamping → B-axis swing milling symmetrical plane

Single Y-axis support back drilled coaxial hole (coaxiality ± 3 μ m)

Device limitations:

The secondary spindle does not have an independent Y-axis and cannot process asymmetric eccentric features.

3. Mass production of general hardware components

Case: Bathroom valve core, bicycle accessories

Efficiency advantage:

Single Y-axis+power head to achieve integrated turning, milling, drilling and tapping

Processing cycle shortened by 40% compared to traditional CNC lathes

Ⅲ- Exclusive application scenarios for 6-axis walking machines

1. High precision asymmetric complex parts

Case: Aviation fuel nozzle, medical puncture needle

Processing requirements:

Main Y1 axis milling 45 ° inclined plane (C1 axis linkage)

Secondary Y2 axis drill * * ± 1.5mm eccentric hole * * (C2 axis rotation)

Precision breakthrough:

The dual Y-axis fully closed-loop control achieves a coaxiality of ± 1.8 μ m between the main and auxiliary shafts, far exceeding the ± 3 μ m of the 5-axis.

2. Multi task synchronous processing scenario

Case: New energy vehicle motor shaft, hydraulic valve block

Process plan:

Front power head (Y1 axis) outer circle+milled spline

Rear power head (Y2 axis) precision inner hole+tapping teeth

Efficiency improvement:

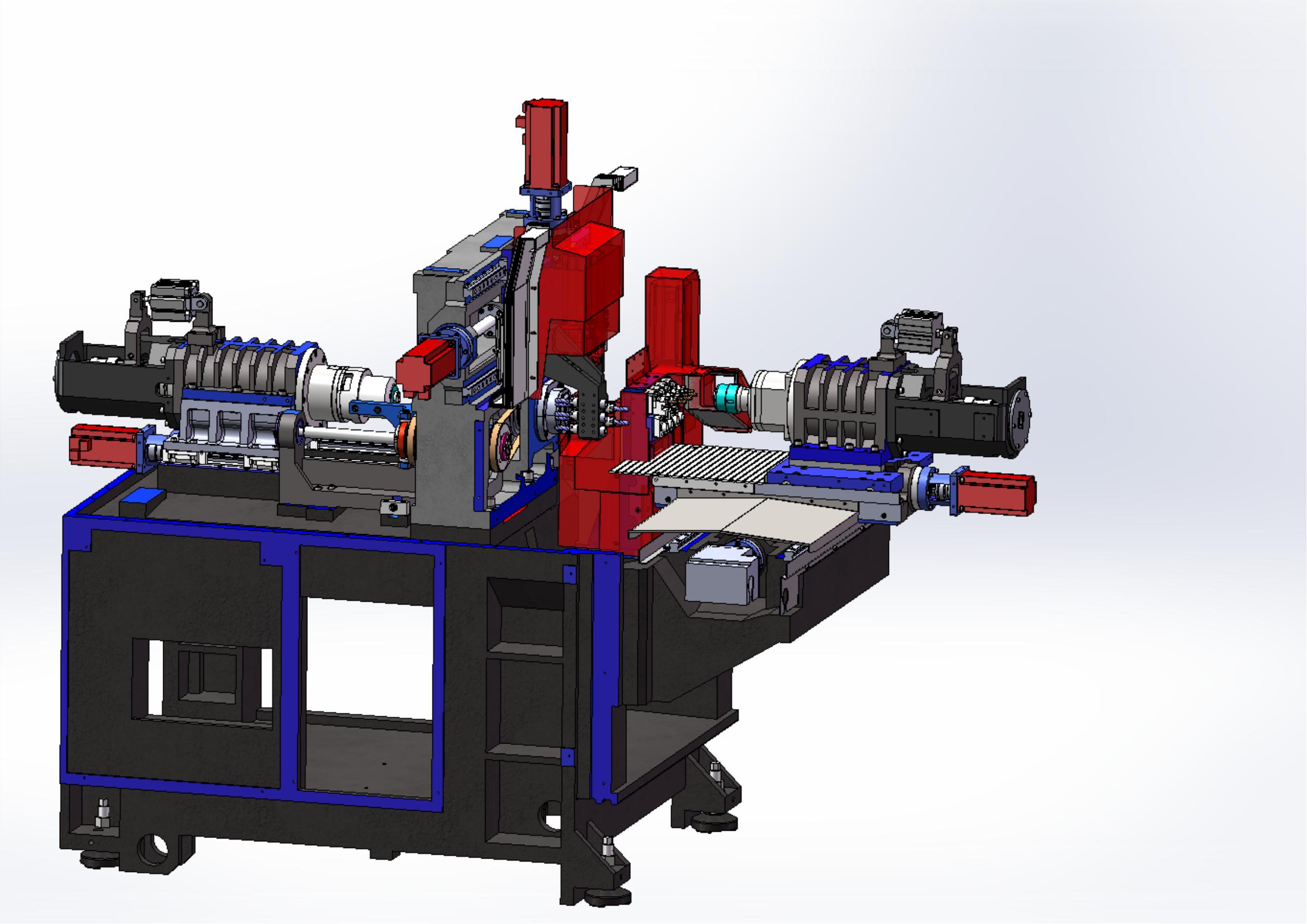

When machining aluminum alloy motor shafts with Taike 266, the cycle time increased from 90 seconds to 55 seconds, resulting in a 39% increase in efficiency.

3. Extreme processing of difficult to process materials

Case: Titanium alloy aviation joint, nickel based alloy screw

Technical advantages:

12000rpm high-speed spindle (5-axis usually 8000rpm)

Dual Y-axis linear motor drives acceleration of 1G, reducing titanium alloy machining vibration

4. Ultra short material precision machining

Case: Electronic connector pins, clock gear shafts

Material utilization rate:

6-axis supports a minimum clamping length of 10mm (5-axis requires 15mm), reducing tail material loss by 33%

Ⅳ-Evaluate production efficiency

5-axis optimization: high proportion of single process (such as pure turning accounting for over 70%)

6-axis optimization: requires synchronous completion of ≥ 3 processes (turning+milling+drilling+tapping)

Ⅴ-Industry application comparison

1. Automotive industry

5-axis: engine connecting rod, gearbox gear shaft (batch>100000 pieces/year)

6-axis: New energy motor shaft, fuel injection system components (accuracy>IT6 level)

2. Medical industry

5-axis: orthopedic screws, surgical handle (surface roughness Ra ≤ 0.8 μ m)

6-axis: Intervertebral fusion cage, puncture needle (eccentric hole position ± 0.02mm)

3. Aerospace

5-axis: Aluminum alloy bracket, standard bolts (machining material hardness<HRC30)

6-axis: titanium alloy impeller, nickel based alloy seal (hardness HRC40-45)

Conclusion: The essence of axis selection is the balance between cost and performance

5-axis walking heart machine is a cost-effective choice, suitable for general parts with medium complexity and large quantities;

The 6-axis walking machine is a technological breakthrough, designed for high-precision, multitasking, and difficult to machine materials.

Taking the TK SA-266 as an example, its dual Y-axis linear motor design makes its machining efficiency in the fields of medical precision parts and aerospace titanium alloys 60% higher than that of the 5-axis model, while the long-term cost is significantly reduced by reducing investment in three equipment.

Please contact us for customized process solutions based on the 3D drawings of the parts and annual production volume when making your selection.