Working Principle of Swiss Type Lathe

A Swiss type lathe (also known as Swiss CNC lathe or sliding headstock lathe) is a high-precision machining tool designed for manufacturing small, complex parts, especially long and slender shafts. Its working principle revolves around the “moving spindle + fixed tool” concept, combined with multi-axis technology for one-stop processing.

Key Operational Principles

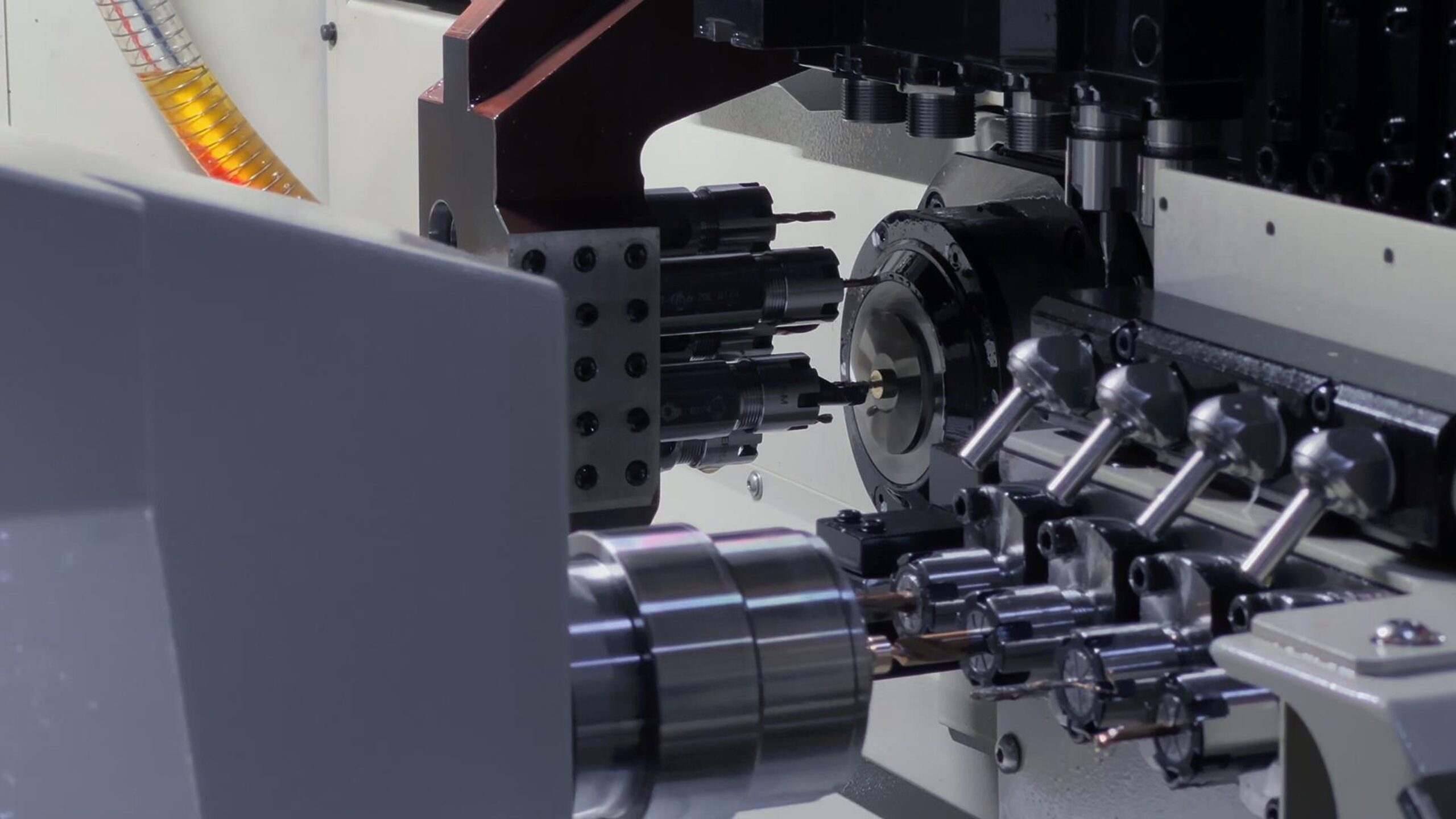

Sliding Headstock & Dual-Spindle System

The lathe features a sliding headstock that moves along the Z-axis, carrying the workpiece, while the cutting tools remain stationary. This design keeps the cutting point close to the guide bushing, minimizing deflection in long shafts (ideal for parts with length-to-diameter ratio >7, e.g., shafts <3mm in diameter). A sub-spindle supports back-end machining without reloading.

Guide Bushing for Stability

The bar stock is fed through a rotating guide bushing, which stabilizes the material during cutting. The bushing can be disabled for non-circular or larger-diameter materials, offering flexibility.

Multi-Process Machining

Equipped with multiple tool turrets (e.g., gang tools, rotary turrets) and X/Y/Z axes, the lathe performs simultaneous operations like turning, drilling, milling, threading, and tapping. The sub-spindle enables secondary machining on the opposite end of the part in a single setup.

Automation & Precision

Integrated automatic bar feeders ensure continuous production, while optional in-process measurement systems achieve micron-level accuracy (±5μm). The dual-spindle independent control reduces clamping errors, making it ideal for medical, aerospace, and watchmaking applications.

Advantages

High Efficiency: Reduces cycle time by 3-5 times compared to conventional lathes through multi-process integration.

Stable Precision: Guide bushing and sliding headstock design minimize vibration and ensure consistent quality.

Versatility: Handles parts from φ0.5mm to φ38mm, including complex geometries and high-volume production.