Difference Between Swiss Type Lathe and Sliding Tool Lathe, and How to Choose

I. Core Differences Between Swiss Type Lathe and Sliding Tool Lathe

Both Swiss type lathes (sliding headstock lathes) and sliding tool lathes are CNC horizontal lathes, but they differ significantly in working principles, structures, and application scenarios:

2. Working Principles

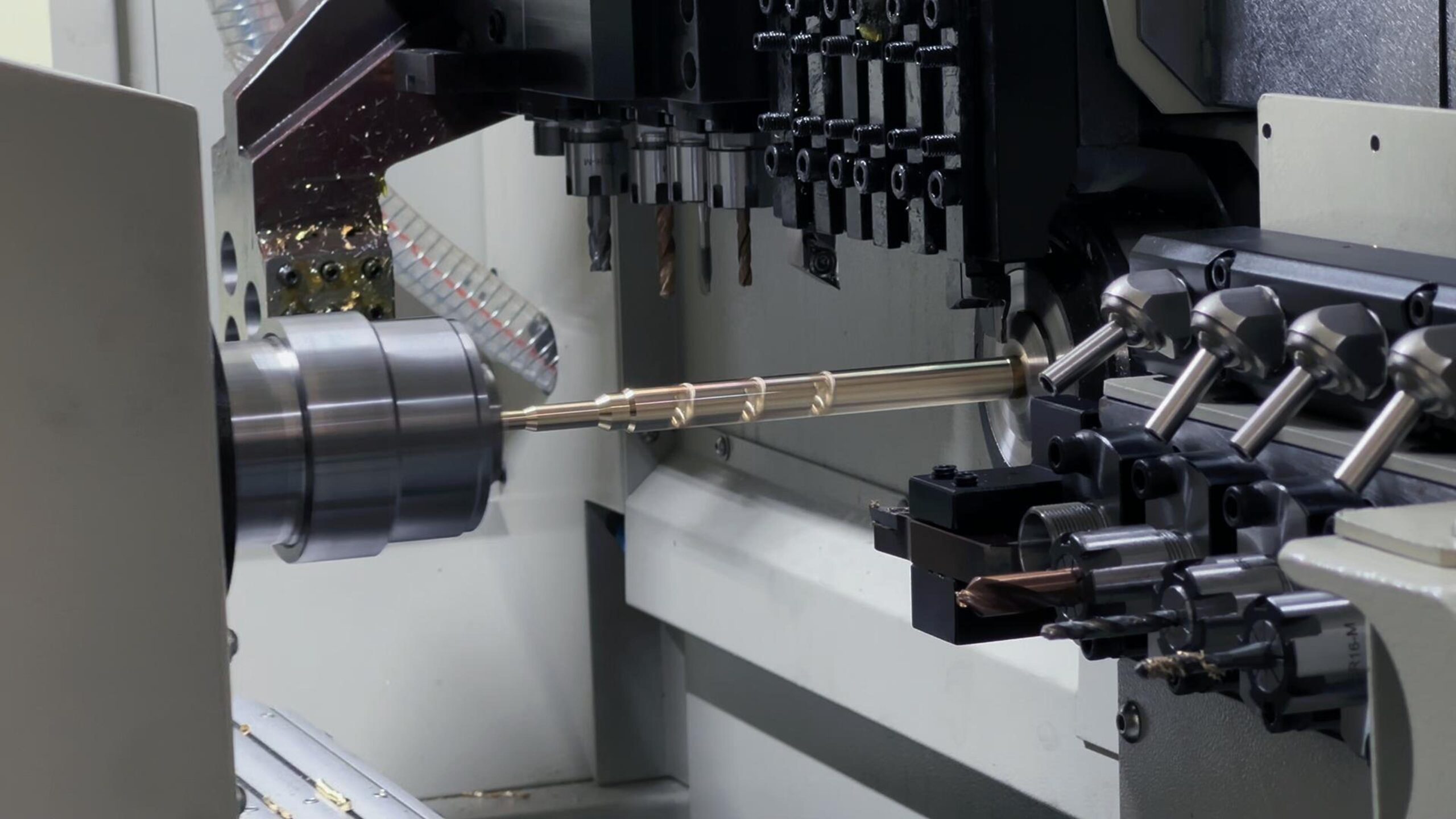

Swiss Type Lathe:

Moving spindle, fixed tools:The headstock slides along the Z-axis to feed the bar stock, while the cutting tools remain stationary. The cutting point stays close to the guide bushing for rigid support.

Guide bushing system:Bar stock rotates with the bushing to reduce deformation in slender parts (suitable for shafts with length-to-diameter ratio >7, e.g., φ0.5-38mm thin shafts).

Sliding Tool Lathe:

Fixed spindle, moving tools:The spindle only rotates, and the tool post moves along X/Y/Z axes for cutting. The workpiece clamping position remains fixed.

No guide bushing:Long shafts rely on steady rests or follow rests, prone to vibration. Suitable for short shafts or complex-shaped parts.

3. Structural Design

Swiss Type Lathe:

Dual spindles (main + sub-spindle), multi-tool turrets (gang/rotary), and multi-axis control (X/Y/Z/C/B).

Equipped with automatic bar feeders for continuous processing of long bars (2-4m).

Sliding Tool Lathe:

Predominantly single spindle, simple tool post, and no sub-spindle.

Supports short-bar single-piece processing with high flexibility, but requires additional fixtures for long shafts.

4. Machining Capabilities

Swiss Type Lathe

Accuracy:Micron-level (±5μm), high rigidity, low deformation

Efficiency:Multi-process integration (3-5x faster than sliding tool lathes)

Parts:Slender shafts, complex (e.g., medical catheters, watch gears)

Material Waste:Tailstock waste (clamping margin required)

Sliding Tool Lathe

Accuracy:Lower accuracy (±10μm+), vibration-prone for long shafts

Efficiency:Single-process, requires multiple setups

Parts:Short shafts, casings, aluminum parts (e.g., auto components, instrument housings)

Material Waste:No tailstock waste, high material utilizationII.

5.How to Choose Between Swiss Type Lathe and Sliding Tool Lathe?

Decide based on the following scenarios:

5.1When to Choose a Swiss Type Lathe

Parts:Slender shafts, precision shafts (length-to-diameter >7), or parts requiring multi-process integration.

Accuracy:±5μm or higher (e.g., medical, aerospace, electronics).

Batch Size:High-volume production (e.g., >500 parts/day) focusing on efficiency

5.2When to Choose a Sliding Tool Lathe

Parts:Short shafts, non-circular sections, or complex casings (e.g., aluminum housings, gears).

Accuracy:Medium-low precision (±10μm+) with tolerance for secondary operations.

Batch Size:Small batches with frequent changeovers or flexible part types.