what is a swiss type automatic lathe

Origin and Development History

I-From Industrial Revolution Enlightenment to Future Manufacturing Innovation.

Swiss type automatic lathe-also known as sliding headstock lathe,cnc swiss lathe,cnc swiss machine、longitudinal turning lathe;

- The birth of Swiss automatic lathes is inseparable from the industrial gene of Switzerland as the “Kingdom of Watches.”

- By the late 18th century, Switzerland’s watch industry entered its golden age, but problems such as low efficiency and large errors in traditional manual watchmaking became increasingly prominent. Plagued by inefficiencies in manual watchmaking (a pocket watch took months to produce) and excessive errors (daily deviation exceeding 10 minutes), the Swiss watch industry faced competition from British mechanical watches.

- Amid this “time crisis,” Swiss craftsmen launched a “precision revolution” to save the industry. To meet the high-precision processing needs of tiny components such as watch gears and escapements, Swiss craftsmen began exploring the possibilities of mechanical automation.

19th Century: The Dawn of Mechanical Automation

- In 1795, Swiss watchmaker Abraham-Louis Breguet invented the first “automatic winding device.” Though not a machine tool, it provided inspiration for mechanical automation.

- In 1872, Swiss engineer Jakob Schweizer invented the first “Automatic Lathe” with an automatic feeding function. By coordinating a cam and dividing disk, it achieved continuous cutting of bar stock. Its processing efficiency was 10 times higher than that of manual labor, with errors reduced to 0.01mm (compared to 0.1mm for manual lathes at the time).

- This invention marked the birth of the prototype of Swiss automatic lathes and established their technical tone of “high precision and high stability.” The emergence of this equipment signaled that Swiss machine tools officially entered the era of “mechanical automation.”

First Half of the 20th Century: “Hardcore Breakthroughs” in Precision Transmission

- Before WWII, the core advantages of Swiss machine tools gradually took shape:

- Transmission System Revolution: In the 1920s, Swiss companies introduced ball screw technology (10 years earlier than the US), improving positioning accuracy from 0.01mm to 0.005mm;

- Material and Process Upgrades: Adopted Meehanite cast iron beds (3 times the vibration damping capability of ordinary cast iron), solving vibration issues during high-speed cutting;

- Specialized Customization: Developed “multi-axis dedicated machine tools” targeting the needs of watches and precision instruments, capable of simultaneously performing 10+ processes like turning, milling, and drilling, achieving part consistency of ±0.002mm.

- Specialized Customization: Developed “multi-axis dedicated machine tools” targeting the needs of watches and precision instruments, capable of simultaneously performing 10+ processes like turning, milling, and drilling, achieving part consistency of ±0.002mm.

- At this time, though Swiss machine tools were not yet widely exported, they became the “backbone of European precision manufacturing”—over 80% of the precision parts for Omega’s tourbillon gears and Leica’s camera shutters were processed by Swiss-made machine tools.

- With the impetus of the Second Industrial Revolution-driven mechanization wave, Swiss automatic lathe technology accelerated its iteration in the early 20th century: Ball screw transmission technology was introduced in the 1920s, significantly improving positioning accuracy; hydraulic control systems became widespread in the 1950s, enabling more complex machining actions;

- And by the 1970s, Swiss enterprises (such as Tornos, Grob, Kellenberger) took the lead in applying CNC (Computer Numerical Control) technology to automatic lathes, driving their transition from “mechanical automation” to “digital intelligence.”

- The introduction of CNC technology was epoch-making. It replaced complex cam mechanisms, making programming more flexible, functions more powerful, adjustments quicker, and precision control reaching new heights. Multi-axis linkage became possible, making it easy to machine complex contours.

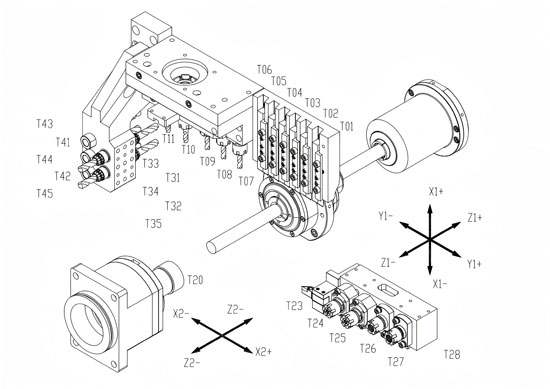

- Swiss CNC lathes differ from traditional lathes in their core design: the spindle moves for machining, with the workpiece (bar stock) clamped by the spindle and moving precisely along the Z-axis (axial direction) while rotating. Tools are fixed on the tool post, not moving with the workpiece, but performing cutting through multi-axis linkage (X, Y, Z axes, etc.).

- This reduces the time for tools to move to the workpiece position for cutting and retracting, minimizes errors caused by repeated tool repositioning, and significantly improves efficiency and precision.

- Composite Processing: Modern Swiss-type automatic lathes (swiss-type lathes) have far exceeded traditional turning. In addition to the turning spindle, they are generally equipped with powerful milling power heads (C-axis, Y-axis linkage), drilling, tapping, knurling, and other capabilities, becoming true turn-mill composite machining centers.

- They can complete almost all processes—turning, milling, drilling, tapping, boring—with a single clamping.

- Intelligence and Automation: Integrated with automatic feeders, online detection, tool monitoring, robotic loading/unloading, etc., they enable long-term unattended production, enhancing efficiency and quality stability. High-speed, high-rigidity, and high-dynamic response designs meet the requirements of difficult-to-machine materials and higher precision.

- At this point, Swiss automatic lathes have officially become “standard equipment” in high-end manufacturing, widely used in precision part processing such as aircraft engine blades, medical orthopedic implants, and optical lens molds.

II. The Development History of Swiss Automatic Lathes Worldwide

Germany: “Precision Hegemony” Born of War – From WWII Armaments to Industry 4.0

- The rise of German machine tools is closely tied to the two World Wars.

- Its development logic is: Military demands drove technological breakthroughs, and post-war civilian markets fueled industrial upgrading.

Pre-WWII: Learning from Switzerland to Lay Technological Foundations

- At the end of the 19th century, Germany was still a “mechanical imitator,” with its machine tool precision lagging 10 times behind Switzerland (error of 0.1mm vs. 0.01mm).

- To narrow the gap, German engineers frequently “stole techniques” from Switzerland: In 1905, A German certain company sent a team to Switzerland to study cam machine tool technology, and in 1910, it launched Germany’s first automatic lathe, reducing errors to 0.02mm.

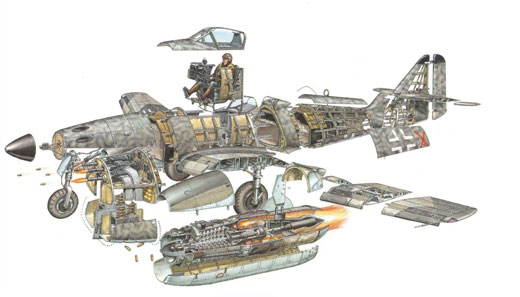

During WWII: The “Precision Engine” of Armament Competition

- After the outbreak of WWII in 1939, Germany’s demand for weapon precision surged: The turret rotation speed of the Tiger Tank needed to be ≤0.1°/second (otherwise prone to jamming),

- and the tolerance of Me-262 jet engine turbine blades needed to be ≤0.003mm (otherwise blades would fracture). To meet these demands, Germany’s machine tool industry underwent “frenzied evolution”.

- Explosion of special-purpose machine tools: To produce gyroscopes for V-2 missiles, Germany developed “five-axis linkage special-purpose machine tools” with a processing accuracy of ±0.001mm;

- Popularization of automated production lines: Through cam + hydraulic control technology, “unmanned continuous processing” of tank tracks and machine gun parts was achieved, increasing the daily production capacity of single production lines by 5 times;

- Material innovation: Collaborating with Krupp to develop “high-speed steel (HSS),” extending tool life by 3 times to meet the needs of high-strength cutting.

Post-War: From Military to Civilian, a Pioneer of Industry 4.0

- After World War II, German machine tool technology was divided up by the United States, the Soviet Union, Britain, and other countries (the Allies acquired some German technical equipment through “looting and dismantling of war trophies,” such as the U.S. “Operation Paperclip” and the Soviet Union’s demolition of factories in East Germany).

- Today, German machine tools dominate the global market with “high reliability and high added value,” accounting for 70% of the high-end market (unit price > 1 million euros). Representative enterprises include DMG MORI, EMAG, and GROB.

Japan: A “Late Bloomer” of Lean Catch-Up – A “Craftsman-Style Comeback” from Imitation to Surpassing

- The rise of Japanese machine tools began with post-WWII “technological hunger” and was driven by the dual engines of “lean production” and “industrial synergy.”

- Post-WWII: “Technological Bottom-Fishing” Amid Ruins

When Japan surrendered in 1945, its machine tool industry was nearly non-existent (only 2,000 old machines remained, with accuracy ≤0.1mm). To rebuild its industry, the Japanese government launched the “Machine Tool Revitalization Plan”. - Introduction + digestion: In the 1950s, Japan imported over 2,000 advanced machine tools from the U.S. and Germany through the “Dodge Plan” and organized enterprises such as Hitachi, Makino, and Mazak to disassemble and study them;

- Talent binding: German machine tool experts (e.g., Professor Klaus from Hamburg University of Technology) were hired as consultants to teach precision transmission, thermal deformation compensation, and other technologies;

- Military-to-civilian demand: During the Korean War, the U.S. ordered large quantities of military supplies (e.g., truck and aircraft parts) from Japan, forcing Japanese machine tools to improve precision (from 0.1mm → 0.02mm).

China: From “Introduction and Digestion” to “Independent Breakthrough” – The “Path to Breaking Through” of Major Country Heavy Equipment

- The development of Chinese machine tools is a history of struggle “from nothing to something, from weakness to strength,” with the key words being “introduction – imitation – innovation.”

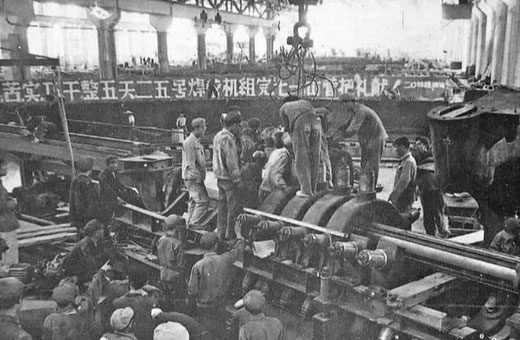

Early Years of the Nation (1949-1978): “Industrial Foundation” Built with Soviet Assistance;

- When New China was founded, there were only 6,500 machine tools nationwide (mostly manual), insufficient to meet industrial needs.

- In the 1950s, China launched the “156 Key Projects,” introducing over 100 high-precision machine tools from the Soviet Union (such as the Soviet “Ural” heavy-duty machine tools) and establishing machine tool factories in Shenyang, Dalian, and other places (e.g., Shenyang No. 1 Machine Tool Factory).

- By 1978, China’s machine tool output reached 133,000 units (accounting for 10% of the global total), but core technologies (such as CNC systems and ball screws) still relied on imports.

Reform and Opening-Up (1978-2000): “Technological Trial and Error” through Joint Ventures and Markets

- In the 1980s, China adopted a “market-for-technology” strategy, establishing joint ventures with German and Japanese enterprises (e.g., Beijing Fanuc, Shenyang Shenchang collaborating with Germany’s Hess).

- However, core technologies (such as five-axis linkage systems and grating rulers) were strictly blocked by foreign parties, leaving Chinese machine tools stuck in the “mid-to-low-end” range (unit price <¥500,000) for a long time.

- By 2000, 90% of China’s high-end machine tool market was dominated by foreign capital.

21st Century: “Independent Breakthrough” under “Made in China 2025”

- After 2000, especially following the proposal of the “Made in China 2025” strategy in 2015, China’s machine tool industry entered a phase of “independent innovation.”

- Technological Breakthroughs: Dalian Guangyang launched a “five-axis linkage CNC system,” breaking the monopoly of Germany’s Siemens and Japan’s Fanuc; Shenyang Machine Tool developed the “i5 intelligent machine tool,” equipped with an industrial internet platform to achieve “remote diagnosis + adaptive machining.”

- Industrial Chain Synergy: Host manufacturers such as Wuxi Turbine Blades and Chengdu Aircraft Industry (Group) collaborated with machine tool factories to jointly develop special machine tools for aviation engine blades (with precision ±0.003mm).

- Global Layout: In 2013, China became the world’s largest machine tool producer (accounting for 38% of global output) and competed with German and Japanese enterprises in Southeast Asian and Middle Eastern markets.

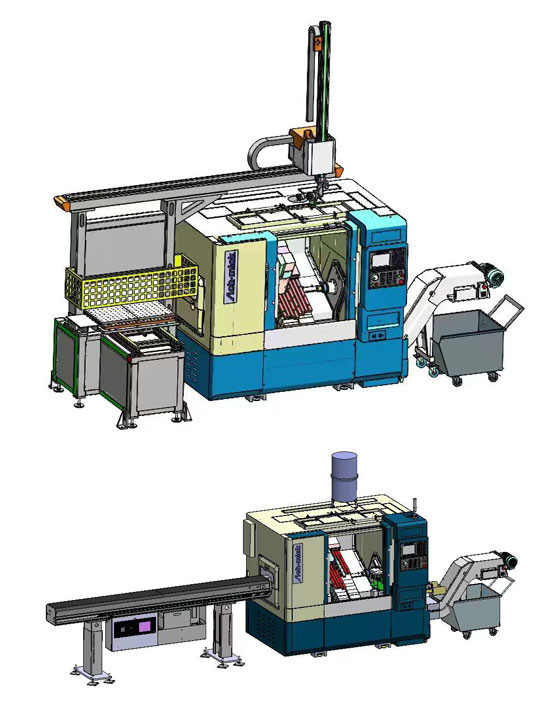

In the field of Swiss-type automatic lathes, Taike is one of the earliest Chinese swiss type automatic lathe manufacturers to develop and sell this type of machine tool, with over 20 years of technical expertise and experience.

- Founded in 2006, Guangdong Taike Intelligent is one of China’s earliest manufacturers of cam automatic lathes. Its products, known for high precision and high stability, are widely welcomed in the domestic market with strong demand.

- The company took the lead in initiating R&D of Swiss automatic lathes, participated in and co-drafted 《China’s industry standard for twin-spindle Swiss-type lathes》, and through decades of technical accumulation, its Swiss CNC automatic lathes have withstood market testing.

- As a Swiss-type automatic lathe factory,Taike provides production solutions for numerous small and medium-sized precision parts manufacturers.

- Its product lineup includes

- 6-axis Swiss-type lathes,

- 5-axis Swiss-type lathes,

- 3-axis Swiss-type lathes,

- Small CNC lathes,

- Cam automatic lathe,

- The company has established supply partnerships with many world-renowned suppliers and exports its machine tools to numerous overseas countries.

The modernization process of China’s machine tool industry is largely a history of introduction, learning, digestion, and catching up.

- Starting from the Soviet model foundation, to the post-reform and opening-up era’s eagerness and introduction of Western (especially Swiss, German, and Japanese) technologies, and now to the arduous breakthroughs and partial achievements in high-end CNC systems, core functional components, and high-end complete machines.

- In the field of Swiss-type Swiss lathes, China has experienced stages from pure importation, to low-end imitation, and then to mid-to-high-end independent innovation represented by enterprises like Taike Intelligent.