Optimizing Tool Usage in Swiss-Type Lathe Machining: Strategies for Extended Tool Life and Enhanced Efficiency

Optimizing Tool Usage in Swiss-Type Lathe Machining: Strategies for Extended Tool Life and Enhanced Efficiency——Practical Methods to Boost Tool Life by 50%+ and Machining Efficiency by 30%

I. Tool Selection: Aligning with Material and Machining Mode

1. Tool Material Based on Workpiece MaterialStainless Steel (304/316):

Opt for Ultrafine-Grained Cemented Carbide Tools (e.g., ISK IC908, 8–10% cobalt content) with TiAlN coating (1100°C heat resistance). Ideal for guide bushing mode when machining slender shafts at speeds over 8000rpm.Titanium Alloy (TC4):

Choose Cermet Tools (e.g., Kyocera CA6535) with TiBN coating for anti-seizing. Suitable for non-guide bushing mode heavy-duty cutting, with cutting speed capped at 80m/min.Aluminum Alloy (6061):

Use PCD diamond tools (e.g., DIJET CD series) without coating to prevent aluminum adhesion, enabling high-speed milling (>300m/min).

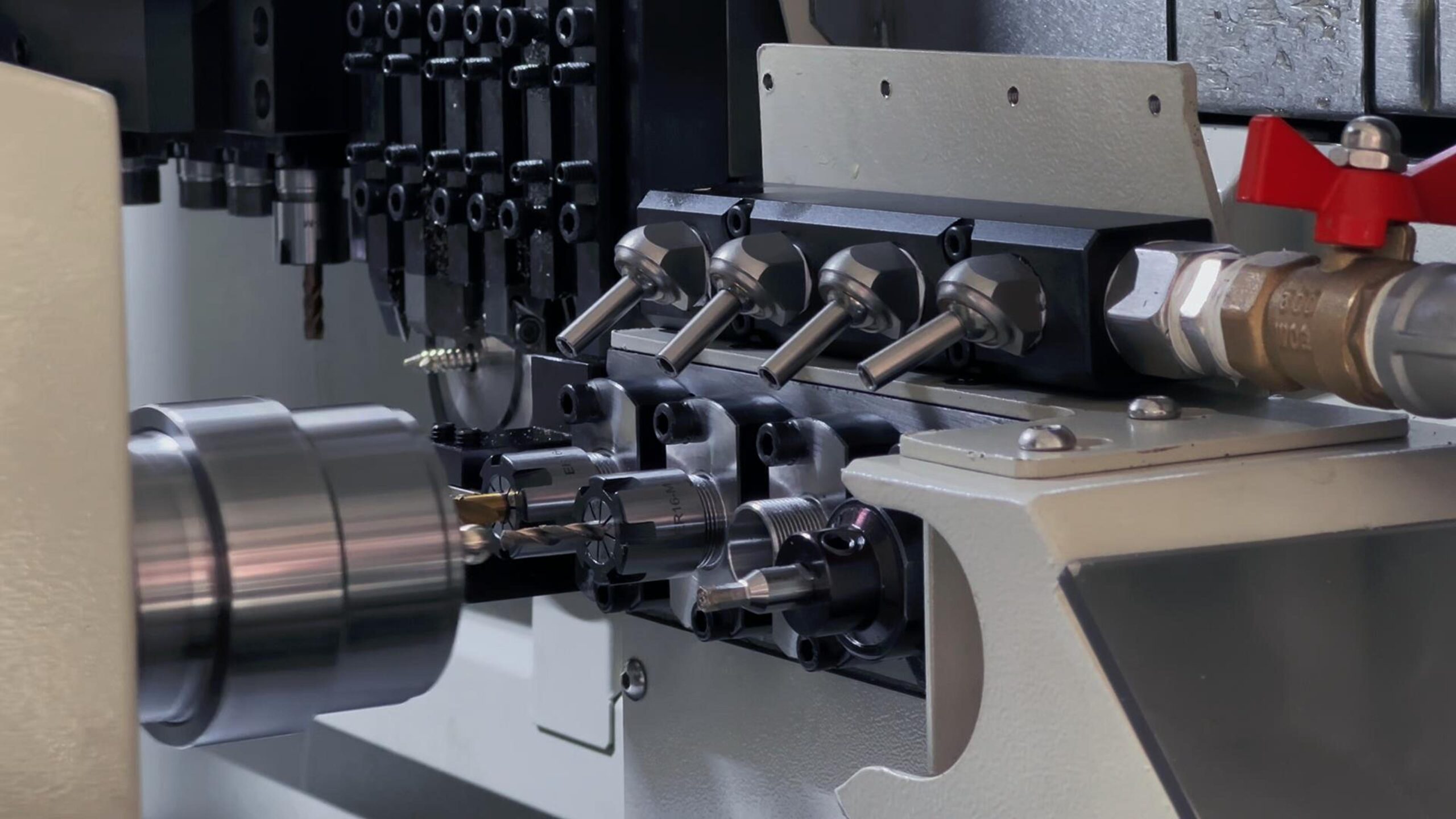

2. Tool Differences Between Guide and Non-Guide ModesGuide Bushing Mode:

Use short-edge tools (overhang ratio <3:1) to minimize vibration. For instance, a φ1.5mm solid carbide drill (5mm edge length) for φ2mm stainless steel shafts, with toolholder runout controlled within 3μm.Non-Guide Bushing Mode:

Employ hydraulic toolholders (e.g., Schunk Tendo, runout <3μm) with corn mills for φ20mm aluminum flanges, reducing single-edge load via multi-flute design.

II. Cutting Parameter Optimization: Balancing Tool Life and Efficiency

1. Taylor’s Tool Life Equation\(V \cdot T^n = C\)Steel: n=0.15, reducing speed by 10% extends tool life by 25%.Titanium: n=0.08, a 10m/min speed increase shortens life by 40%.

2. Stage-Based Parameter AdjustmentRoughing:

80–100% rated speed, 120% feed rate, 0.8–1.5mm depth of cut for maximum efficiency.Semi-Finishing:

90% speed, 100% feed, 0.2–0.5mm depth to balance life and precision.Finishing:

70–80% speed, 80% feed, <0.1mm depth for extended tool life.

III. Cooling and Lubrication: The Hidden Factor in Tool Longevity

1. Coolant SelectionWater-Based Coolants:Stainless/Titanium: Chlorine-based extreme pressure coolant (e.g., Castrol Mobilcut 320, 5–8% concentration).Aluminum: pH-neutral coolant (e.g., Blaser SW 102) to prevent corrosion.Oil-Air Lubrication:

For high-speed milling (>5000rpm), apply 0.5–1.2ml/h oil at 0.4–0.6MPa pressure.2. Cooling PositioningTurning (Guide Mode):

Direct nozzles 1–2mm behind the cutting point with 2–3MPa pressure for annular cooling.Deep Hole Drilling:

Use internal-coolant tools (e.g., BIG Kaiser twin-edge drills) with 5–8MPa coolant to flush chips.

IV. Tool Clamping and Edge Treatment

1. Clamping PrecisionLaser-align live tooling for <5μm runout.

Quarterly calibrate spindle Coaxiality with a Φ10mm test bar, allowing <3μm runout.

2. Edge EnhancementEdge Rounding:

Carbide tools with 0.02–0.05mm radius (e.g., Walter EdgeIQ) to resist chipping.Coating Post-Treatment:

Ultrasonically clean TiAlN-coated tools to reduce friction coefficient to <0.15.V.

Machining Strategies: Reducing Abnormal Tool Wear

1. Avoiding Intermittent CuttingTurning: Use 45° ramped entry instead of perpendicular engagement, reducing impact force by 60%.Milling: Adopt helical ramping (1–2mm pitch) to decrease axial force by 35%.2. Layered Cutting TechniquesDeep Holes (L/D >5):

Peck drilling with 1×D retraction every cycle to prevent chip jamming.Threading:

3-pass cutting (60%/30%/10% depth) to halve single-edge load.

VI. Tool Monitoring and Maintenance1. Predictive MaintenanceVibration Threshold:

Replace tools when spindle vibration exceeds 2.8mm/s (ISO 1940 G2.5).Current Monitoring:

Trigger alarm at 15% current increase (e.g., 15A → 17.25A).2. Regrinding and Discard CriteriaRegrinding:

Carbide tools at VB=0.3mm, HSS tools at VB=0.1mm.Discard:

Chip damage >0.5mm or toolholder bend >0.1mm (checked via dial indicator).

VII. Case Study: Stainless Steel Slender Shaft Machining

Before Optimization:Generic carbide drill (φ3mm), Vc=80m/min, Fn=0.1mm/r.80 parts/edge life, 12% chipping rate, 18 seconds/part.

Optimization Steps:Upgraded to TiAlN-coated Ultrafine-Grained Cemented Carbide (Sandvik Coromant CB7025).Adjusted parameters: Vc=70m/min, Fn=0.12mm/r (20% higher feed).

Applied internal cooling + oil-air mix at 4MPa.Results:87% Longer Life: 150 parts/edge.35% Faster Cycle: 13 seconds/part.33% Cost Reduction: ¥2,400 → ¥1,600 per 10,000 parts.