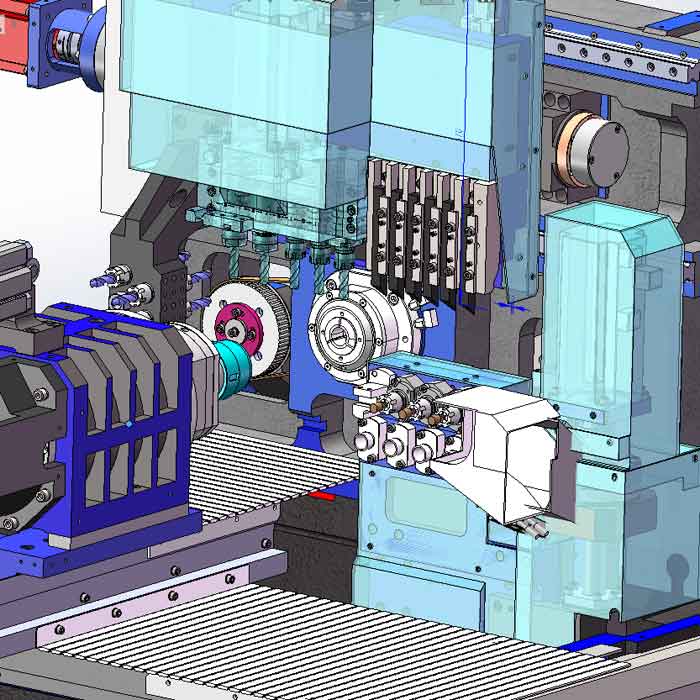

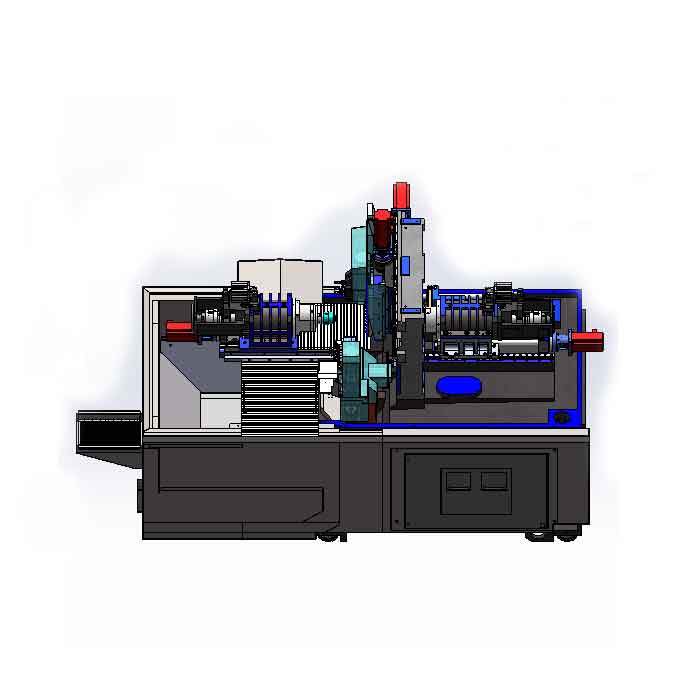

This Swiss machine tool has composite functions of turning, milling, drilling, and tapping, and is particularly suitable for large-scale, multi variety, high-precision machining tasks of slender shafts and small complex rotating parts. Our products have high precision and accuracy, and the main components are made of internationally renowned brands. Our production process and technology are in a leading position in China. The product is widely used in fields such as electronic communication, drones, optical instruments, home appliances, automotive and motorcycle parts, medical accessories, special motors, watches, fasteners, bathroom accessories, etc..

Characteristic:

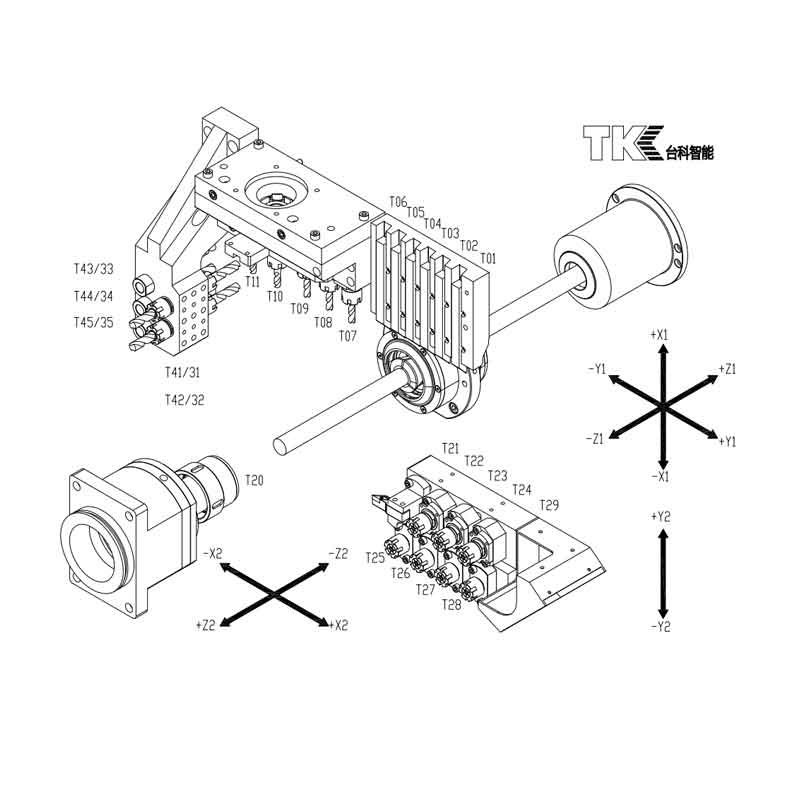

- 6-axis simultaneous machining can meet various complex processes, and fully automated processing saves labor.

- Dual-spindle synchronous machining enables one-hit complete machining without secondary clamping

- Dual-channel CNC system: SYNTEC/FANUC(optional )

- Electric spindle high-speed turning and milling composite machining

- Modular Tools Layout, Multi-axis Combined Operation; Stable, High-speed, Highly-efficient, Easy Operation

Specifications:

| (Item) | SA266 | Stand accessories | |||||||

| Max.machining diameter | φ26mm | 01. CNC functions SYNTEC 200TB 02. 10.4-inch color LCD display 03. Chucking sleeve(Main/Sub) 04. Synchronous rotary guide bushing 05. O.D.tool*6 06. C axis control(Main/Sub) 07. Chucking device(Main/Sub) 08. Transverse rotating tools*5 09. I.D.tool holder 10. Y2 axis unit 11. Lubrication device(with level sensor) 12. Door switch 13. Separate iron chip storage tank 14. Separate cutting oil tank 15. RCD 16. Product ejector 17. Desandman 18. Guide bushing air seal 19. Main spindle air seal 20. Sub spindle air seal 21. Sub spindle air purge 22. Signal lamp 23. Work light(LED) 24. Product conveyor 25. Oil cooler | |||||||

| Max.headstock stroke | G.B. | 255mm | |||||||

| N.G.B | 2.5D | ||||||||

| Turning tools | Number | 6 tools | |||||||

| Model | □12mm | ||||||||

| Face tool holder | Number | Front-end working | 5 tools | ||||||

| Rear-end working | 2 tools(Max.5 tools) | ||||||||

| Max.drilling | Fixed tool axis | φ10mm | |||||||

| Max.tapping | Fixed tool axis | M8*P1.25 | |||||||

| Corss tool unit | Number | 5 tools | |||||||

| Model | 5-ER16 | ||||||||

| Max.drilling | φ8mm(ER16) | ||||||||

| Max.tapping | M6*P1.0 | ||||||||

| Max.milling | φ10mm | ||||||||

| Max.slotting notch | Wide:1.5,deep:4mm | ||||||||

| speed | ER16 | 6,000rpm | |||||||

| Drive motor | 1.0KW | ||||||||

| Rapid traverse rate | Z1 axis | 32m/min | |||||||

| X1 axis | 32m/min | Optional accessories | |||||||

| Y1 axis | 32m/min | 01. Polygon maker tool holder 02. Face replaceable tool holder 03. Swiveling tool holder 04. Thread whirling 05. Hobbing tool holder 06. Fixed guide bushing 07. Rear discharge device 08. 7.0MPa coolant unit 09. 10Mpa coolant unit 10. 14Mpa coolant unit 11. Oil mist collector 12. Small diameter shockproof device 13. Cutting oil flow detection device 14. Extinguisher 15. Automatic Bar Feeder 16. Chip conveyor | |||||||

| Main spindle speed | 10,000rpm | ||||||||

| Main spindle indexing angle | C axis control(0.001°) | ||||||||

| Main spindle motor | 2.2/3.7KW | ||||||||

| Main spindle through-hole diameter | φ22mm | ||||||||

| Coolant Capacity | 170L | ||||||||

| Coolant motor | 0.4KW | ||||||||

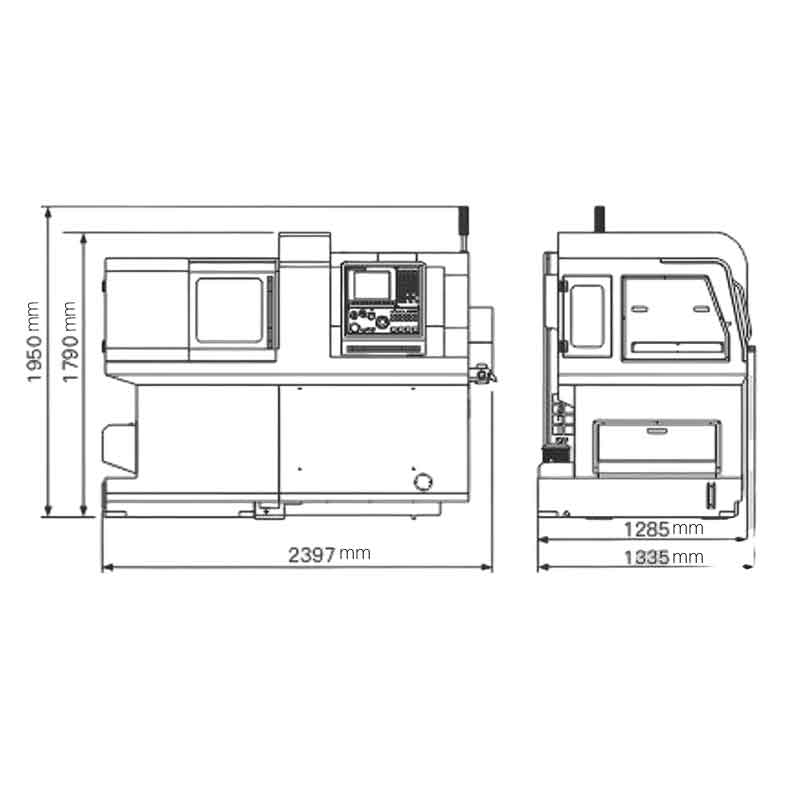

| Dimensions of machine | 2310*1300*1720mm | ||||||||

| Weight | 2600kg | ||||||||

| SUB SPINDLE ATTACHMENT | |||||||||

| Max.machining diameter | φ26mm | ||||||||

| Max.length of front pick | 80mm | ||||||||

| Max.emerged length | 50mm | ||||||||

| Back processing | Number | ER16 | 8 tools(Contains optional) | ||||||

| Max.drilling | Fixed tool axis | φ8mm | |||||||

| Power-driven | φ6mm | ||||||||

| Max.tapping | Fixed tool axis | M8*P1.25 | |||||||

| Power-driven | M6*P1.0 | ||||||||

| Rapid traverse rate | Z1 axis | 32m/min | |||||||

| X1 axis | 24m/min | ||||||||

| Y1 axis | 24m/min | ||||||||

| Sub spindle speed | 8,000rpm | ||||||||

| Sub spindle indexing angle | C axis control(0.001°) | ||||||||

| Sub spindle motor | 1.5/2.2KW | ||||||||

Reviews

There are no reviews yet.