How Swiss CNC Automatic Lathes Work

Swiss-type CNC lathes are specialized precision machine tools designed for high-accuracy machining of complex, slender parts. Originally developed for Switzerland’s watchmaking industry, they are now widely used in high-end manufacturing sectors such as medical devices, aerospace, and electronics. Below is a breakdown of their working principle, core advantages, differences from conventional CNC lathes, and acquisition costs.

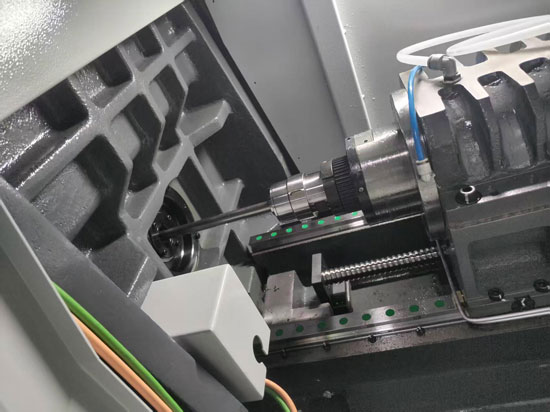

I-The core structure and working principle of Swiss-type CNC lathes revolve around the "sliding guide bushing (Sliding Headstock)". The main principles are as follows:

- Traditional CNC lathes clamp the bar stock only at the front (by the chuck), leaving the rear end unsupported (especially when the part has an L/D ratio > 5:1).

- This unsupported length can cause bending deformation under cutting forces, compromising precision.

Swiss-type lathes solve this with a “dual-support” design:

- Front End: The main spindle (chuck) clamps the bar stock.

- Rear End: A sliding guide bushing supports the tail end of the bar stock.

- Rear End: A sliding guide bushing (bar feeder with sliding bushing) supports the tail end of the bar stock. This bushing moves synchronously with the bar stock toward the spindle (known as “going to the heart” or “walk-up” feeding), maintaining rigid support along the entire cutting length.

- This minimizes the unsupported bar length (only the section between the bushing and cutting tool), significantly reducing vibration and deformation—making it ideal for small-diameter (φ0.5–φ32mm), long-length (L/D > 10) slender parts (e.g., medical tubing, aerospace shafts).

- This bushing moves synchronously with the bar stock toward the spindle (known as “going to the heart” or “walk-up” feeding), maintaining rigid support along the entire cutting length.

Multi-Axis CNC System & Advanced Features

- Swiss-type lathes are equipped with high-precision CNC systems (e.g., Fanuc, Syntec, Mitsubishi) and integrate multiple advanced modules:Main Spindle: Rotates and feeds the bar stock axially.

- Guide Bushing: Moves synchronously with the bar stock to support the rear end.

- Y-Axis Power Tool Turret: Enables radial (perpendicular to the spindle axis) milling, drilling, and tapping.

- Sub-Spindle (Secondary Spindle): Controlled via servo synchronization, it works in tandem with the main spindle (e.g., gripping one end while the sub-spindle holds the other for cutting-off, secondary machining, or two-sided processing).

- This allows simultaneous two-end machining and complex multi-operation processing in a single setup.

Automated Bar Feeding: High-Efficiency Continuous Production

- Swiss-type lathes are paired with automatic bar feeders (hydraulic or servo-driven) that continuously feed the bar stock into the guide bushing.

- After machining, the sub-spindle cuts off the finished part, which either drops automatically or is collected by a robot arm.

- This enables fully automated, unattended production—ideal for high-volume manufacturing.

II. Core Advantages of Swiss-Type CNC Lathes (Swiss-Type Automatic Lathes)

- Compared to conventional CNC lathes, the advantages of Swiss-type lathes are primarily reflected in three key dimensions:

- precision,

- efficiency,

- application specificity.

Superior Machining Precision

Dimensional Stability for High L/D Ratio Parts:

The full-length support from the sliding guide bushing eliminates bending deformation caused by unsupported bar stock. For slender shaft-type parts, roundness and straightness errors can be controlled within 0.005mm (conventional lathes typically exceed 0.02mm).

Enhanced Surface Quality:

The precise fit of the guide bushing (with a clearance < 0.001mm) reduces friction between the bar stock and the bushing. This enables machined surface roughness to reach Ra0.6μm (conventional lathes generally range from Ra0.8 to 3.2μm).

Exceptional Machining Efficiency

Integration of Multiple Machining Operations:

Through coordinated operation of the Y-axis (radial), C-axis (spindle rotation), and sub-spindle, Swiss-type lathes complete multiple processes—including turning, slot milling, drilling, tapping, and parting—in a single setup (conventional lathes require multiple setups, leading to accumulated clamping errors).

Continuous Automated Production:

The “heart-cutting” mode—combining automatic bar feeding with sub-spindle parting—enables a single machine to achieve a daily output 3–5 times higher than conventional lathes (particularly suitable for high-volume production of small parts with diameters < 10mm).

Precise Application Specificity

Specialization in Slender and Precision Parts:

- Swiss-type lathes excel in machining small-diameter, high-precision components with stringent requirements,

- such as:Medical devices (e.g., orthopedic screws, cardiac stents);Aerospace micro-shafts (e.g., engine fuel nozzles);Electronic components (e.g., connector pins).

Strong Capability in Machining Complex Shapes:

- Via transverse milling on the Y-axis and rotational control on the C-axis, these lathes directly machine complex features—including arcs, bevels, and helical grooves—without requiring additional milling machines or machining centers (a necessity for conventional lathes).

III. Key Differences from Conventional CNC Lathes

The differences between Swiss-type CNC lathes and conventional CNC lathes (CNC lathes, also known as "turret lathes") are essentially a divergence in design philosophy and application scenarios. A detailed comparison is as follows:

| Comparison Dimension | Swiss-Type CNC Lathe | Conventional CNC Lathe |

| Core Structure | Sliding guide bushing + bar stock feeding (dual support); material moves along the tool, with the tool remaining nearly stationary. | Fixed chuck + tailstock (single support, or no tailstock); the tool moves while the material stays stationary. |

| Workpiece Type | Small-diameter (φ0.5–φ32mm), high-aspect-ratio (L/D > 10) slender precision parts. | precision parts.Medium/large-diameter (φ20–φ500mm), short-length conventional parts. |

| Machining Precision | Roundness/straightness ≤ 0.005mm; surface roughness Ra0.6μm. | Roundness/straightness ≤ 0.02mm; surface roughness Ra1.6–3.2μm. |

| Process Integration Level | Multi-axis linkage (Y/B-axis + sub-spindle); multiple operations completed in a single setup. | Typically 2–3 axes (X/Z-axis); requires multiple setups or re-fixturing. |

| Production Efficiency | High (automatic bar feeding + continuous processing, suitable for high-volume production). | Moderate (relies on manual/robotic loading/unloading, suitable for medium/small-volume production). |

| Typical Applications | Medical devices, aerospace micro-shafts, electronic connectors, motor shafts. | General mechanical parts (e.g., flanges, bolts, bushings). |

Comparison of Machining Lengths

- Generally, a five-axis Swiss-type automatic lathe in guide bushing mode can achieve a maximum machining length of 200mm. TAIKE’s Model 205 Swiss lathe, with a maximum machining length of 255mm, leads the industry in this capability.

- In contrast, conventional CNC lathes can only reach up to 100mm. While adding a tailstock can extend this length, it significantly reduces spindle speed, lowering production efficiency. Additionally, for workpieces longer than ~60mm, material deformation under pressure becomes highly likely.

- Cam-automatic lathes, meanwhile, are limited to a maximum machining length of just 35mm. Swiss lathes thus offer broader applicability for diverse workpiece lengths.

Comparison of Machining Efficiency

- Due to the structural design of Swiss automatic lathes, the spindle headstock (gripping the workpiece) can perform precise linear motion along the machine bed, while the cutting tools remain nearly stationary. This minimizes tool retraction time after machining, saving substantial time.

- Moreover, dual-spindle Swiss lathes employ a sub-spindle machining solution: after the main spindle completes machining and parts off a segment, the sub-spindle grips the workpiece, retracts to the rear tool station, and performs secondary operations (e.g., drilling, milling). This halves the machining process. A five-axis Swiss lathe reduces machining time to 60% of that required by conventional CNC lathes.

- Additionally, Swiss lathes eliminate the need for multiple clamping operations, enabling one setup to complete all complex processes and avoiding precision losses from re-clamping. With higher automation, a single operator can manage up to 10 machines.

- In contrast, conventional CNC lathes require cutting tools to move to the workpiece, cut, retract to the origin, and then allow the next tool to move in—adding 2 seconds per tool for non-cutting movement. For complex workpieces requiring 10+ tools, non-cutting time exceeds 20 seconds.

- They also lack customizable modular functions: after machining the front end of a part, the rear end often requires processing on another machine, incurring precision losses (>0.001mm) from repositioning and additional labor costs. These factors drive up production expenses and make it difficult to meet tight precision requirements for high-end clients.

Under the same machining time, Swiss lathes nearly double efficiency, producing more parts and increasing profit margins.

Comparison of Procurement and Production Costs

Taike Model 205 Swiss automatic lathe as an example:

- Switzerland (Tornos): As the pioneer of Swiss-type lathes, Tornos delivers ultra-high precision and stability but at high maintenance costs. Procurement cost: Around $100,000.

- Japan (Citizen, Star ): Renowned for watchmaking-grade precision, these brands excel at micro-part machining. Procurement cost: Around $70,000

- China (TAIKE): A leading Chinese Swiss lathe manufacturer and co-drafter of the Dual-spindle Precision Slitting CNC Lathe industry standard, TAIKE emphasizes rigidity and stability. The procurement cost is approximately ~$50,000, with relatively low overall operating expenses. For a cost-effective option, the practical and economical Model203 Swiss-type lathe has a procurementcost of under~ $30,000.”

- Conventional CNC Lathes (Model 20): Procurement cost is ~$20,000. However, complex parts often require multiple lathes for separate operations, incurring higher costs for factory space, rent, and labor. Total usage costs may even exceed those of Swiss lathes, while precision struggles to meet high-end client demands.

Selection Recommendations:

- If your main products are parts that are very slender (with a very large L/D ratio), small-diameter (primarily Ø0.5mm–Ø32mm), structurally complex, require extremely high precision, and are produced in large batches, the Swiss-type automatic lathe (Swiss lathe) is the preferred or even the only choice.

- If your products are mainly short/stubby parts (with a small L/D ratio), disk/sleeve-type parts, have general precision requirements or larger dimensions, or involve diverse machining tasks in small batches, conventional CNC lathes (turret lathes) may be a more economical and flexible choice.

If you have products that require evaluation of machining solutions, please contact us. We can provide free machining solutions and machining time estimation, and support sample production!