What is a CNC Lathe? –

An introduction to all different types of CNC lathe machines

This article provides an introduction to CNC lathes from the aspects of their definition, structural classification, processing type classification, model classification, equipment applications, and the purposes of the parts being machined.

This article provides an introduction to:

I-CNC Lathe (full name: Computer Numerical Control Lathe Machine) is an automated metal cutting machine tool controlled by a computer numerical program. It is primarily used for machining rotating parts (such as shafts, discs, and sleeve-type components).

Advantages:

- Higher precision (repeatability can reach micron-level accuracy),

- Greater efficiency (automation reduces manual intervention),

- Enhanced flexibility (different parts can be quickly switched by modifying the program).

They are ideal for batch production or the manufacturing of high-precision parts.

II - CNC lathes can be classified from multiple dimensions such as structural form, control capability, and functional complexity, as detailed below:

Feature comparison:

Processing rigidity

The main issue with flat-bed lathes lies in the fact that when performing vertical cutting (especially radial cutting forces), the cutting forces — particularly the radial forces — act directly on the radially weakest direction of the workpiece.

For example, when machining long, slender shafts, the radial force can cause the workpiece to bend and deform, ultimately affecting machining accuracy (such as exceeding tolerance in cylindricity).

However, for heavy-duty cutting or machining short-diameter disc-type parts, due to the simple and natural structure of the bed, flat-bed lathes with hard rails generally offer better stability and higher precision.

🔹 Example:

- When machining a φ6 mm, 110 mm long slender shaft (made of 45# steel):

- On a flat-bed lathe, the radial cutting force is about 800 N, which can easily cause the shaft to bend and deform by more than 0.1 mm;

- On a 45° slant-bed lathe, the radial component of the cutting force is reduced to 300–400 N, and the deformation can be controlled within 0.03 mm, resulting in a precision improvement of more than 3 times.

Chip Removal Capability:

Flat-Bed Lathe:

- The cutting area is on a horizontal plane, causing chips to easily accumulate under the workpiece, around the guide rail covers, or near the cutting tool.

- Requires forced cooling assistance (such as high-pressure water jets) for chip evacuation.

- If chips are not removed in time, they may be re-cut by the tool (“chip nibbling”), leading to poorer surface roughness (e.g., increased Ra value) or even scratching the workpiece surface.

- Due to the inclined bed, the cutting area naturally forms a “downward sloping channel.”

- Chips (especially curled chips from tough materials like steel and cast iron, or fragmented chips from aluminum alloys) will slide directly down to the chip removal groove at the bottom of the bed under gravity.Chips hardly accumulate in the cutting zone or on the workpiece surface.

Classification by Guide Rail Type:

Hard Rail Lathe

- Extremely High Rigidity:Integrated structure with no joint gaps, capable of withstanding enormous radial cutting forces and impact loads.Slow Movement Speed:

- Suitable for heavy-duty cutting and large stock removal, such as roughing/semi-finishing of large shafts, flanges, and forgings.

- Typical Applications:Heavy industry, shipbuilding, wind power, and manufacturing of large-scale equipment.

Linear Rail Lathe :

- Medium Rigidity:Modular structure with minor joint gaps, offering weaker impact resistance.Fast Movement Speed:

- Ideal for machining small and medium-sized parts, such as those in 3C electronics, automotive components, medical devices, and precision instruments.

- Market Presence:More widely used in the market compared to hard rail lathes.

- Extremely High Rigidity:The hydrostatic oil film can bear extremely high loads (even higher than hard rails), suitable for hundred-ton ultra-heavy workpieces.

- Extremely High Precision:No mechanical contact or wear, achieving positioning accuracy up to 0.0005 mm (micron level), ideal for ultra-precision machining.

- No Heat Generation:Liquid friction generates almost no frictional heat, avoiding thermal deformation that could affect precision.

- Very High Cost:Requires a high-pressure hydraulic system (including oil pump, oil filter, oil temperature control system), making the overall machine cost 3–5 times higher than hard rail lathes.

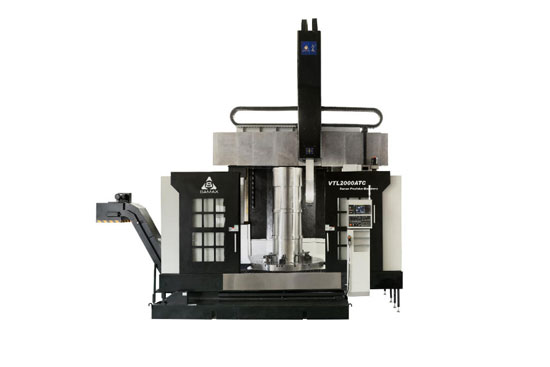

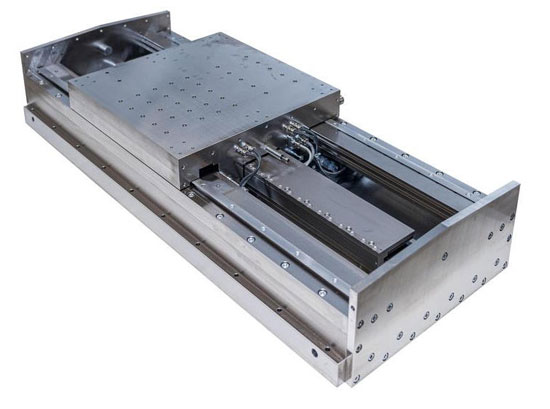

- The Fixed Head Lathe is categorized as a “CNC lathe that achieves feed motion through tool movement, based on a flat-bed or slant-bed structure.”

- It is the most basic and widely used type of CNC lathe for shaft-type part machining, corresponding to what we commonly refer to as a “CNC lathe”.

- This category includes commonly seen machines on the market such as:cnc turning centre,cnc turn mill machine,cnc turning milling center、Turret Lathes,gang tool lathe ,Cam Automatic Lathes ,automatic lathe machine

Sliding Headstock CNC Lathe:

- A precision CNC lathe based on the longitudinal (in-line) cutting structure, where machining is achieved through axial feed of the workpiece (the headstock moves along the workpiece axis).

- Because it originated in Switzerland (initially developed for machining high-precision watch components), it is also commonly referred to as a ”Swiss-type lathe”.

It serves as the core equipment for machining high-precision shaft-type parts. - (Also known as: CNC Swiss Type Lathe, Swiss Longitudinal turning Lathe、cnc swiss machine、swiss turning machine、swiss lathe machine、swiss turning lathe)。

| Classification dimension | Fixed Head cnc Lathe | Sliding Headstock CNC Lathe |

| Core motion logic | The cutting tool moves while the workpiece remains fixed (rotates only) | Workpiece moves (axial feed), tool is fixed |

| Industry alias | Ordinary CNC lathes, Gang type CNC lathe、cnc metal lathe | longitudinal turning lathe、swiss machine、swiss lathe、swiss machine tool、swiss turning lathe、swiss type automatic lathe |

| Classification affiliation | Traditional type of CNC lathe with “cutting tool leading feed” | Precision type of “workpiece-dominant feed” in CNC lathes |

| Type of machined parts | For short rotating parts with diameter greater than length (such as disks, flanges, gear blanks) | Shaft-type parts with a relatively large shaft diameter ratio (such as motor shafts, spline shafts, knurled shafts) |

| Degree of automation | Single-piece processing using hydraulic chucks involves more manual operations; small machines may also use vibration plates, robotic arms, or bar feeders | Essentially all are fully automatically processed, equipped with oil-film bar feeders or robotic arms, and vibratory bowls. |

| Machining accuracy | General accuracy – Large part error can reach 0.1mm, small machines can achieve 0.01mm precision | High precision – Conventional machine tools can achieve an accuracy of 0.01mm; high-end machine tools can achieve 0.005mm. |

Classification by Number of Controlled Axes

- 2-Axis CNC Lathe:

Controls only the X-axis (radial direction) and Z-axis (axial direction). It is suitable for machining simple rotational parts (such as smooth shafts and ordinary discs). Typically, this category includes 15/20/25-type parallel-tool post CNC lathes. - 3-Axis CNC Lathe:

Based on the 2-axis configuration, it adds a C-axis (workpiece rotation axis). This enables indexing positioning (e.g., machining polyhedrons) or simple milling in conjunction with a power turret (serving as the basis for turning-milling integration). - 5-Axis CNC Lathe:

main spindle + sub-spindle (Z1/Z2) with X1/X2, Y1 axes (the C-axis, for spindle rotation, is generally not counted separately). It can machine complex curved surfaces (such as impellers and irregular contours) and belongs to high-end composite machining equipment.

Additionally, rarely seen 6-axis, 7-axis, or 9-axis CNC lathes are essentially 5-axis systems with additional configurations added.

Functional Classification:

- Five tools operate simultaneously, enabling fast machining.Mechanical structure is more durable and stable.

- Difficulty achieving precision below 0.01 mm, and difficult to set up and adjust.Limited machining length.

- Suitable for small-sized, easy-to-machine parts with low precision requirements.

- Economical and simple-structured machine, suitable for small and simple parts.Fewer functions available.

- Longer non-cutting time due to the back-and-forth movement of tools toward and away from the workpiece.

CNC automatic lathe machine:

- An upgraded version of traditional cam auto machine, maintaining high efficiency while improving precision.

- Combines some functions of both cam lathe machine and gang type cnc lathe

Turret Lathe :

- Generally equipped with a servo turret, without built-in power functions (though a 4+4 power milling unit can be added separately).

- Older models can use both gang type and turret, but rigidity is relatively weak.

turn-mill machine:

- Usually equipped with a power turret, and can be fitted with a tailstock for machining longer shaft-type parts.

- Equipped with a swivel head, tool magazine for quick tool changes according to machining needs, and supports multi-axis linkage.

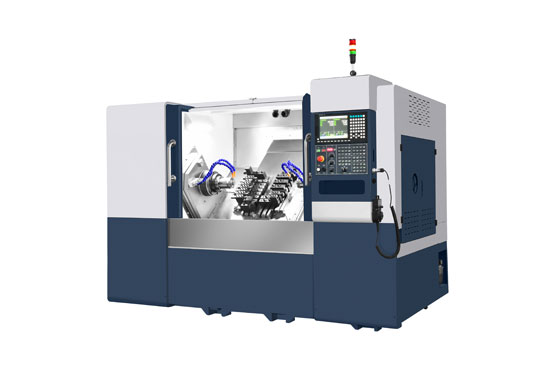

cnc swiss lathes :

- A precision CNC lathe based on the longitudinal (in-line) cutting structure, achieving machining through axial feed of the workpiece.

- Capable of simultaneous dual-axis machining, doubling machining efficiency.

Dual-Spindle gang type cnc lathe :

- Combines functions of both gang type lathes and Swiss-type lathes.

Features moving spindle box + moving tool machining. - Less efficient than Swiss-type lathes, with fewer available functional modules and slightly lower rigidity.

- Can be equipped with a simple power unit to enable turning-milling, and has slightly higher rigidity than Swiss-type lathes.

III-Interpretation of Common Model Classifications (How to Choose the Right CNC Lathe)

- Models such as 15, 20, 36, 46, 52, and 65 refer to the maximum bar stock diameter that can be machined without a hydraulic chuck.

- For example:

- The 20-type lathe has a maximum machining diameter of 20 mm,

- The 52-type lathe has a maximum machining diameter of 52 mm.

- With single-part machining, you can use hydraulic chucks of different sizes to achieve machining of bar diameters from 200 mm to 500 mm or even larger.

Swiss Type Lathe :

- Models such as 07, 12, 20, 26, 32, and 38 refer to the maximum bar stock diameter that can be machined.

- For example:

- The 125-type refers to a five-axis Swiss-type lathe with a maximum bar diameter of 12 mm,

- The 326-type is a six-axis Swiss-type lathe with a maximum bar diameter of 32 mm.

- Common Swiss-type models include:

Three-axis Swiss-type lathe 203,

Five-axis Swiss-type lathe 205,

Six-axis Swiss-type lathe 266.

How to Choose the Right Lathe Based on Part Diameter Range:

Select a more economical and suitable lathe based on the diameter range of parts your factory needs to process.

- Larger lathes offer a wider machining range,

- Smaller lathes are more compact, with faster machining speeds, lower procurement costs, and smaller footprint.

🔹 For example:

- The widely used 46-type CNC lathe on the market has a wide machining diameter range, but it is not as compact in structure as smaller lathes. When machining very small parts, the 15-type lathe may offer better efficiency.

- Also Consider Extreme Size Limitations:

- For instance, when machining a 12 mm diameter steel bar, a 125-type Swiss-type lathe can barely handle it, but due to insufficient cutting rigidity, the machining speed is slow and surface finish is poor.

- However, when machining a 12 mm diameter brass part, the 125-type can easily produce perfect parts.

In cases involving high-hardness materials, the 205-type may be the most suitable choice.

IV. Types of Machined Parts:

1. Shaft-Type Parts

- Definition:

- Rotational parts where the length is much greater than the diameter (e.g., cylindrical, stepped, or tapered shafts).

- Typical Applications:

- Motor shafts,Transmission shafts,Knurled shaft,Spline shaft,Medical bone screw,Printer shaft,etc.

- Machining Features:

- Requires operations such as:Outer diameter (OD) turning,Facing (end surfacing),Chamfering,Grooving,

- Thread cutting (e.g., trapezoidal threads, rolled threads),Taper cutting (e.g., Morse taper), etc.

- For high-precision shafts, rough and finish turning may also be required before grinding.

🔹 Such long shaft parts are generally more suitable for machining on a Swiss-type lathe

2. Disc-Type Parts

- Definition:

Rotational parts where the diameter is greater than the length (e.g., disks, flanges, gear blanks).Typical Applications:

Gear,blanks,Pulleys,Flywheels,Clutch discs,Hydraulic valve covers, etc. - Machining Features:Focuses on machining:End faces,Outer diameters,Inner holes (drilling / boring),Grooves (sealing grooves, keyways),

- Chamfers,

Complex discs may require machining of annular grooves or evenly spaced holes, which often need indexing devices.

🔹 Generally machined using a hydraulic chuck, typically on a 46-type gang type tool lathe or a turn mill machine、turret lathe.

3. Fastening Parts:

- Definition:

Connecting or fastening components are mechanical parts used to join or secure two or more parts together, forming a single integrated structure to meet specific functional requirements. - Typical Applications:Automotive hydraulic struts,Hydraulic cylinder sleeves,Valve sleeves,Non-standard fasteners,Screws, nut blanks, etc.

- Machining Features:

It is essential to ensure the coaxiality between the inner hole and the outer diameter. Machining operations include: - Drilling,Boring,Outer diameter turning,Grooving,Chamfering, etc.

- There are many types of such parts, and both Swiss-type lathes and CNC lathes have suitable machining applications.

4. Complex Curved Surface Parts

- Definition:

Rotational parts featuring non-circular curved surfaces (such as arcs, parabolas, hyperbolas) or irregular contours. - Typical Applications:

Root sections of aero-engine blades (with arc transitions),Blades of high-speed hair dryers,

Camshafts in precision instruments (with non-uniform diameters),Spherical lens mounts in optical equipment, etc. - Machining Features:

Requires multi-axis coordinated machining (such as 2-axis linkage for turning arcs, or using a power turret for profile machining) to achieve precise cutting of complex contours.

🔹 Generally requires machining on multi-axis high-end machines, such as Swiss-type lathes or turn mill machine。

Thank you for your reading!

- If you have metal parts that require evaluation of machining solutions, please feel free to contact us. We can provide free machining solutions and processing time estimates, and we also support sample production.Recommend the most suitable cnc metal lathe for you

- Welcome to learn more about our CNC lathe and Swiss-type lathe product series!