What is the difference between a Swiss lathe and a CNC lathe ?

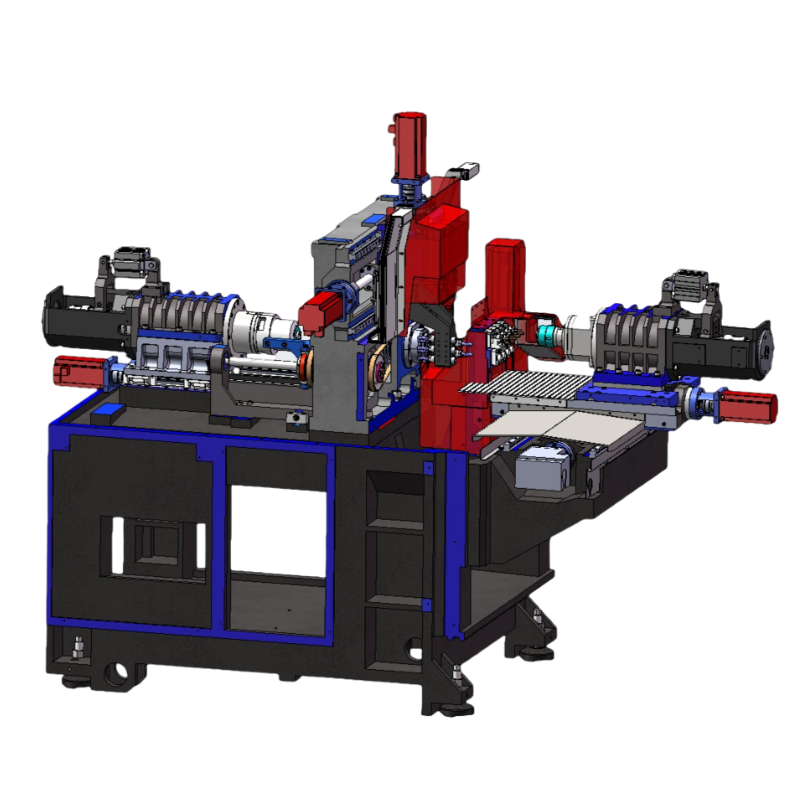

Swiss lathes( sliding headstock machine)and CNC lathes are two common types of equipment in the field of metal cutting, with significant differences in machining principles, structures, applicable scenarios, and advantages/disadvantages.

Simply put, a Swiss-type lathe is a specific branch of CNC lathes, more suitable for processing small, precision, complex, and slender parts,

while traditional CNC lathes (usually referring to fixed-headstock CNC lathes, gang tool lathe, are more general-purpose, suitable for processing parts with a wider range of sizes and relatively simpler designs.

I. Core Machining Principles (The Most Fundamental Difference): Workpiece Movement vs Tool Movement

Swiss Lathe :

- Workpiece Axial Movement (Z-axis Movement): The spindle holds the workpiece and moves along the Z-axis (axial direction), passing through a fixed tool spindle head that integrates multiple cutting tools (such as turning tools, drills, milling cutters, etc.).

- Tool Rotational Cutting (C-axis Function): The tool spindle head not only holds the tools but also has rotational capability (C-axis), enabling power tool operations such as milling, drilling, and tapping. The tools rotate around the stationary or axially moving workpiece to perform cutting.

- Machining Method: The workpiece is cut while moving (or combined with tool rotation for complex machining).

Conventional CNC Lathe :

- Workpiece Rotation: The spindle holds the workpiece and rotates at high speed.

- Tool Movement for Cutting: Turning tools mounted on the tool turret move along the X-axis (radial) and Z-axis (axial) to approach the rotating workpiece for cutting.

- Machining Method: The workpiece rotates while the tools feed and move for cutting.

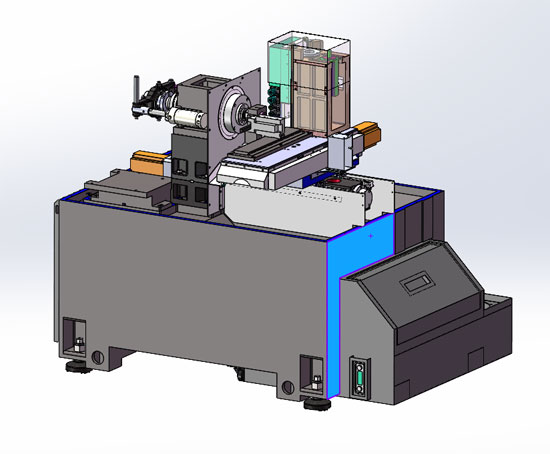

II. Key Structural Design Differences: Compact & Efficient vs General-Purpose & Flexible

- More Complex and Compact Structure.

Typically Features a Dual-Spindle Design (Main Spindle and Sub-Spindle/Rear Spindle). The main spindle completes front-end machining, after which the sub-spindle takes over the workpiece to perform back-end machining. - One-setup completion of all or most processes is a core advantage.

- Equipped with a Powerful Tool Spindle Head, which integrates multiple (even dozens of) tool stations. It can hold both fixed tools (turning tools) and powered tools (rotating milling cutters, drills, etc.).

- Usually Includes an Independent Guide Bushing Support System to support slender workpieces, preventing vibration and bending during machining.

- Conventional CNC Lathe:

- Relatively Simple and Direct Structure.

- Commonly Uses a Single Spindle, with Only a Few High-End Machines Employing Dual Spindles (Rarely for Workpiece Transfer).

- Primarily Relies on a Tool Turret to hold turning tools. The turret can move along the X-axis and Z-axis. High-end turning centers may be equipped with a power turret (where some tool positions have rotational capabilities for milling, drilling, etc.), but the rigidity and flexibility of their powered tools are generally inferior to the dedicated tool spindle head of a Swiss-type lathe.

- Typically Lacks a Guide Bushing Support. (Some manufacturers design external synchronous guide bushings, but they are less stable and durable.) The workpiece is only held by the spindle chuck, making it prone to centrifugal wobbling when machining slender parts (L/D ratio > 5), leading to reduced precision (e.g., out-of-roundness, poor surface roughness).

III. Suitable Workpiece Characteristics

Swiss-Type Lathe :

- Small Precision Parts: Especially excels in machining workpieces with diameters smaller than 32mm (typically even smaller, such as watch components, medical device parts, electronic connectors, etc.).

- Slender Shaft Parts: The guide bushing support makes it highly suitable for machining long, thin shafts with high length-to-diameter ratios, avoiding chatter marks and bending.

- Complex Parts:Capable of easily performing multiple compound operations—such as turning, milling (flat surfaces, grooves, special shapes), drilling, tapping, knurling, slotting, and parting—in a single setup, achieving “turn-mill” integrated machining. This reduces process transfers and clamping operations.

- High-Volume Production: Designed from the outset for high-precision, high-efficiency mass production.

Conventional CNC Lathe:

- Broader Size Range: Can machine workpieces from small to large sizes (even several meters in diameter), offering greater versatility.

- Relatively Simple Shafts and Disc/ sleeve Parts: Its primary strength lies in turning operations (outer diameters, inner holes, end faces, threads, grooving, parting, etc.).

Limited Capability for Complex Parts:

- For non-turning operations like milling, it relies on a power turret (which generally has inferior efficiency, rigidity, and flexibility compared to a Swiss-type lathe), often requiring multiple machines or processes.

- Suitable for Single Pieces, Small Batches, and High-Volume Production: More adaptable with a wider range of applications.

IV. Core Advantages

Swiss-Type Lathe:

- Ultra-High Precision and Stability: Eliminates secondary clamping errors with a single setup; guide bushing support reduces vibration; rigid structure ensures excellent dimensional accuracy and geometric tolerance control.

- Extremely High Efficiency (Especially for Complex Small Parts): Multiple tool stations enable simultaneous or rapid tool switching; sub-spindle shortens machining cycles; composite machining eliminates the need for equipment changeovers.

- Complex Machining in a Single Setup: Significantly improves precision and efficiency while reducing management costs.Excels in Machining Slender Workpieces.

Conventional CNC Lathe:

- Greater Versatility: Can handle a wider range of rotating parts in various sizes.

Lower Cost (Relatively): - Lower equipment purchase and maintenance costs compared to Swiss-type lathes of similar specifications.

Gentler Learning Curve: More intuitive operation and programming (primarily for turning). - Larger Workpiece Size Range.

Power Turret Provides Some Composite Capability (Turning Centers).

V. Limitations

- Significant Workpiece Size Restrictions: Primarily limited to small-diameter parts.

- High Equipment Cost: Complex structure, high technical barriers, and expensive pricing.

- More Complex Programming & Debugging: Requires handling multi-axis synchronization, multi-tool coordination, and sub-spindle synchronization, demanding high-level CAM software support.

- High Tooling System Cost: The tool spindle head and its accompanying tools (especially powered tools) are generally more precise and expensive.

- Secondary Clamping Errors: Complex parts require multiple clamping operations or multiple machines, affecting precision and efficiency.

- Prone to Deformation & Chatter When Machining Slender Parts: Lack of effective support.

- Lower Efficiency for Complex Parts: Compared to Swiss-type lathes’ single-setup machining, it requires more processes and equipment, resulting in poorer consistency.

- Limited Composite Capability: Even with a power turret, efficiency, and flexibility are generally weaker than a Swiss-type lathe when machining complex features.

VI. Summary Comparison Table:

| Characteristics | swiss type automatic lathe | Traditional CNC lathe |

| Core principle | Workpiece axial movement (Z-axis) + tool rotational cutting (C-axis) | Workpiece rotation + tool movement (X/Z) |

| Spindle type | Electric spindle, precise C-axis rotation indexing | Mechanical spindle, there is backlash in the belt and gear, and there is an error in C-axis indexing |

| Tool movement | Tool magazine box (C-axis rotation + possible radial movement) | X-axis (radial), Z-axis (axial) movement |

| Core structure | Dual spindle + fixed tool magazine box (including power tools) + guide sleeve | (Rotating) spindle + moving tool turret (may have a power tool turret) |

| Greatest advantage | Dual spindle machining reduces machining time by half, with ultra-high precision and stability, high efficiency (suitable for complex small parts, long and thin parts), one-time clamping for all processes, no need for manual re-clamping, high automation level, space and labor saving, low comprehensive use cost | Strong versatility, wide range of workpiece sizes, relatively low cost |

| Common types | Swiss-type CNC lathe, dual spindle lathe,twin spindle lathe,double spindle cnc lathe、cnc swiss machine | Bar machine, tool turret machine, turning and milling compound machine tool, turning and milling compound center, double-spindle tool turret CNC lathe |

| Typical workpieces | Small-sized (≤ 32mm, 38mm processing efficiency is not as fast as double turret CNC lathe), precision, complex, long and thin shafts, mass production | No center through-hole limitation: The workpiece does not need to pass through the center of the main shaft, the size range is wide (from small to large), and hydraulic chucks can be used |

| Machining length | Maximum length can reach around 600mm | Generally around 100mm, and the tool turret machine tool can reach about 550mm with the addition of a tailstock, but the cutting speed is very slow |

| Composite machining | Powerful (C-axis + X/Z + Y-axis), saves tool movement time | Limited (depending on the power tool turret), mainly turning, slow tool change speed, and non-cutting time accounts for a large proportion |

| Accuracy performance | Higher (one-time clamping + guide sleeve, workpiece movement reduces tool overhang, reduces vibration; coaxiality ≤ 0.01mm) | High, but may decrease after multiple clamping, tool cumulative repeat positioning error, tool movement may cause vibration due to excessive overhang |

| Efficiency (for complex parts) | Extremely high (multiple tools simultaneously/fast + full process), one-time clamping completes turning, milling, drilling, tapping and other processes, reduces air travel | Relatively low (requires multiple processes/equipment), complex parts require multiple clamping, and positioning error accumulates |

| Machining of slender parts | Excellent (guide sleeve support) | Difficult (prone to tool vibration and deformation) |

| Material compatibility | Suitable for easy-to-cut materials (copper, aluminum, free-cutting iron), due to the limitation of tool size, cutting efficiency for high hardness metals slows down | Compatible with a wider range (chrome steel, cast iron, stainless steel), large-diameter tools have stronger cutting rigidity, and can process high-hardness materials. |

| Automation types | Oil film bar feeder, vibrating tray + robotic arm loading and unloading, high automation level | Disk parts are generally manually operated, requiring multiple clamping, and some small bar parts can use automation |

| Programming/Operation | More complex (multi-axis coordination), complex parts mainly programmed by computer, simple turning manually programmed | Relatively simple and intuitive (mainly turning), manual programming is more common |

| Operating system | Commonly used dual-channel system, or multi-channel system of high-end machine tools | Conventional machine tools use a single-channel system |

| Application scenarios | Medical devices, watches, electronic connectors, precision hardware, automotive shafts, etc., suitable for mass production and high consistency parts | Suitable for general machinery manufacturing, larger-sized shaft sleeve parts, mold inserts, disk parts, and suitable for small and medium batches or multi-variety switching |

VII. Cost Comparison

When selecting equipment, a comprehensive evaluation should be made based on the specific dimensions, complexity, precision requirements, production volume, and cost budget of the parts.

| Comprehensive cost comparison | swiss type automatic lathe | Traditional CNC lathe |

| Equipment cost | Five-axis machine tools for machining diameters under 26mm are usually 2 – 3 times more expensive than CNC lathes. | The procurement cost of single – axis lathes for machining diameters below 46 mm is low. The price of single – axis tool turret lathes is comparable to that of Type 203 Swiss – type turning centers, and the cost of multi – axis machine tools for machining diameters above 46 mm is approximately the same as that of Type 32 Swiss – type turning centers. |

| Maintenance cost | The guide bush and spindle synchronous mechanism need regular calibration and replacement, and the price of accessories is high. | The maintenance of core components (spindle, tool turret) is simple, and spare parts are easy to obtain. |

| Operation threshold | High. It requires mastering dual – spindle synchronous control, guide bush parameter setting, multi – process programming. It has high requirements for the skills of operators. | The programming logic is simple (tool path control), which is easy for beginners to get started. Even novice technicians can operate it. |

| Maintenance cost | The downtime cost is high. High – quality cutting oil is required. Maintenance and after – sales service are more complex. | It has a simple structure and is easy to repair. Low – cost cutting fluids can be used, but the cumulative maintenance cost of multiple machine tools for complex workpieces is higher. |

| Labor cost | Fully automatic processing. One person can operate 20 lathes. | Only one piece can be processed on one machine per person during single – piece machining. That means more senior supervisors and technicians with average operation skills are required. |

| Space cost | A Swiss – type turning center can achieve the efficiency of multiple single – axis CNC lathes, occupy a small area, save rent costs and electricity fees. | Multiple lathes are required to complete one working procedure, resulting in a large floor area and high water and electricity consumption. |

| Product added – value | Most of them are parts with high precision requirements and technical thresholds, with large profits. | The accuracy is medium. For mass – market products with fierce market competition, the price is low and the profit margin is thin. |

| Usage cost comparison | The cost is lower for mass production and parts with high consistency. | It is suitable for small and medium – batch production or multi – variety switching, as well as simple machining that does not require automation.To produce high – precision and high – profit products, it cannot meet the requirements. |

VIII. Selection Recommendations: How to Choose?

Evaluate Workpiece Characteristics:

- If machining slender, precision, small-diameter parts (e.g., φ5mm×50mm pins) with high-volume production → Choose a Swiss-type lathe .

- If machining short, stout, large-diameter parts (e.g., φ100mm×50mm flanges) or lower precision requirements → Choose a conventional CNC lathe .

Evaluate Production Needs:

- For high-volume production and multi-process integration (turning, milling, drilling in one setup) → Swiss-type lathe (significant efficiency advantage).

- For small batches or single turning operations → Conventional CNC lathe (lower cost, higher flexibility).

Evaluate Precision Requirements: - If extremely high coaxiality & roundness (e.g., ≤0.01mm) is required → Swiss-type lathe.

For standard precision (e.g., ≤0.02mm) → Conventional CNC lathe.

Thank you for your reading!

Taike As a 20-year experienced swiss cnc machine manufacturers, we specialize in providing precision machining solutions.

For your metal parts requiring machining evaluation, we offer:

✅ Free machining solutions

✅ Processing time estimation

✅ Sample production support

Explore our complete range of CNC lathes and Swiss-type lathes today!

Welcome to contact us!