Characteristic:

- Compared to traditional cam automatic lathes, this machine improves accuracy while adopting a gang lathe structure, further enhancing rigidity. As a result, it can process a wider variety of high-hardness metals, greatly expanding the machining range.

- There is no need to customize cams for each product, which further reduces maintenance and production costs

- The programming is simple and easy to learn. New operators can get started within just a few days, solving the problem of difficulty in recruiting skilled technicians.

- It supports remote programming assistance and operational guidance, solving the issue of difficult setup and operation commonly found in cam-driven automatic lathes.

- With significantly improved intelligence and full automation capabilities, a single operator can manage up to 20 machines, drastically reducing labor costs.

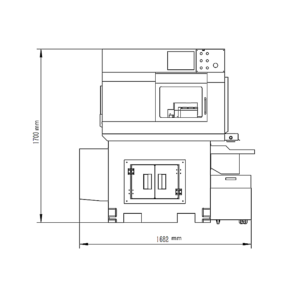

- The right side features a slant bed lathe structure, which enhances chip removal and allows for the installation of more turning tools and milling cutters.

- The mini lathe machine can be equipped with live tools holders to perform complex machining operations such as side turning, face milling, and drilling.

Configuration List and Mechanical Parameters of SC-15 cnc cam automatic lathe | ||

| Specifications | ||

| (Item) | SC-15 | Standard Configuration of Main Machine: 01.Synchronous spindle unit and clamping device |

| Maximum machining diameter | φ15mm | |

| Maximum drilling diameter | φ8mm | |

| Maximum tapping | M6*1.0 | |

| Maximum milling (end – face rotation) | φ10mm | |

| End – face rotation power | 1.0kW | |

| Maximum rotational speed of end – face rotation | 6000r/min | |

| Thread – cutting function for turning | Offers | |

| Multi – tool synchronous machining function | Offers | |

| Spindle power | 4.0kW | |

| Maximum spindle speed | 6000r/min | |

| Tool holder | □8mm | |

| Number of tool installations | 11 | |

| Stroke of X1, 2, 3, 4, 5 axes | 30mm | |

| Stroke of Z1, 2 axes | 55mm |

|

| Stroke of X6 axis (cross – slide) | 190mm | |

| Stroke of Z3 axis (cross – slide) | 150mm | |

| Stroke of X1, 2, 3, 4, 5 axes | 0.4kW | |

| Power of Z1, 2 axes | 0.4kW | |

| Power of X6 axis (cross – slide) | 0.4kW | |

| Power of Z3 axis (cross – slide) | 0.4kW |

|

| Rapid traverse speed | 30m/min | |

| Center height of spindle | 1110mm | |

| Coolant capacity | 80L | |

| Power of coolant motor | 0.4kW | |

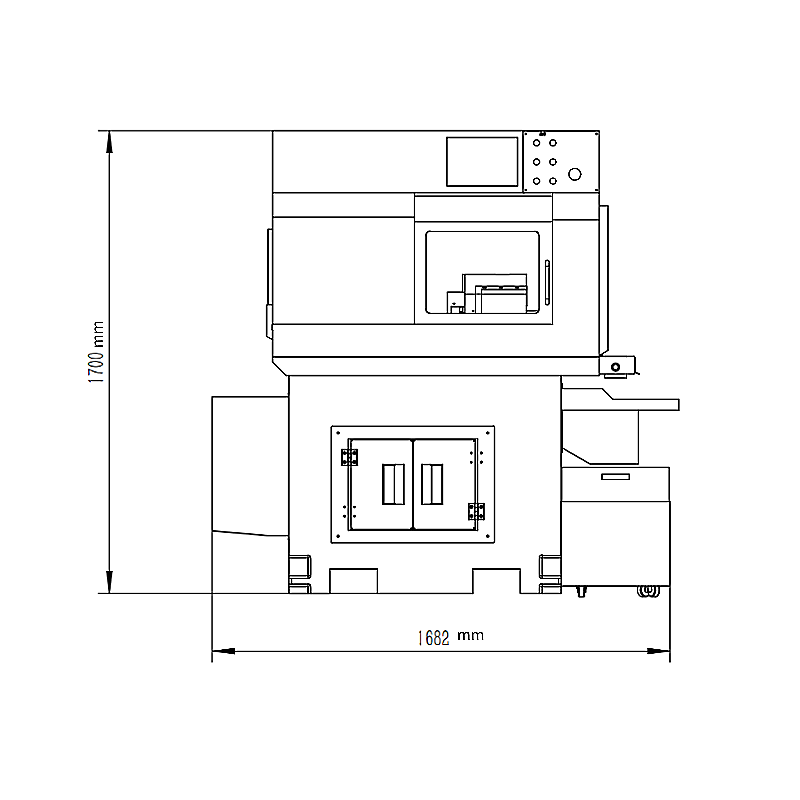

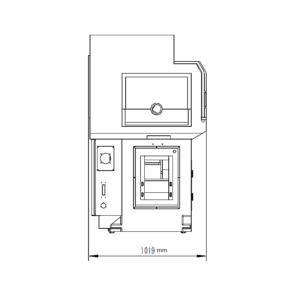

| Overall dimensions (length * width * height) | 1770mm×950mm×1560mm | |

| Machine weight | 1700kg | |

Reviews

There are no reviews yet.