Characteristic:

1. Core Structural Advantage: Expertise in Precision Machining of Slender Shafts

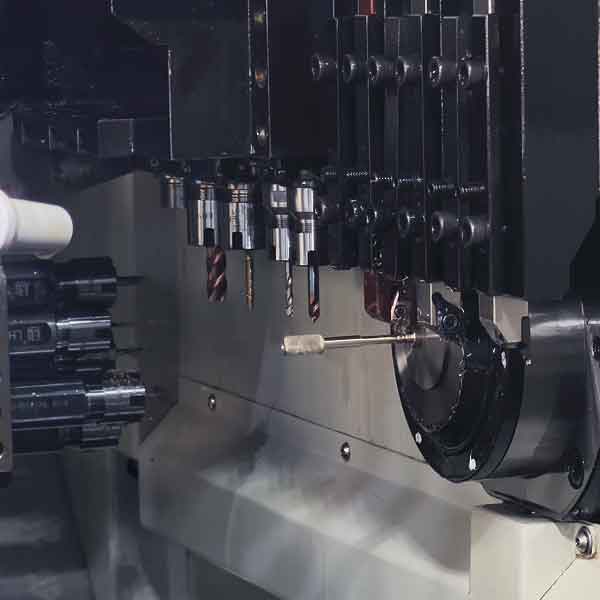

- It adopts a “moving headstock, fixed tool” structure. During machining, the slender shaft workpiece only performs rotational movement, while the headstock drives its feed. This effectively avoids the overhang vibration issue associated with traditional moving tool posts. This design fundamentally reduces “chatter vibration,” ensuring superior surface finish, dimensional tolerances, and exceptionally high concentricity difficult to achieve with multiple setups.

2. Highly Concentrated Processes, Ensuring Datum Uniformity

- The workpiece can complete multiple operations such as turning, milling, drilling, and tapping in a single setup. All machined features use the spindle centerline as a unified datum, completely eliminating cumulative errors caused by multiple setups or transfers between machines. This is particularly suitable for shaft-type components requiring multi-faceted precision and complex positional relationships.

3. Cost-Effective Compound Machining Solution

- While achieving the aforementioned precision turning-milling compound capabilities, its mechanical structure is simpler compared to complex multi-axis synchronous Swiss-type lathes, resulting in significantly lower acquisition and maintenance costs. It provides an ideal solution for small to medium-batch production that combines precision, efficiency, and economy.

4. Enhanced Production Efficiency and Flexibility

- It consolidates machining tasks from multiple machines, simplifying the production process and material flow, and shortening lead times. It demonstrates strong adaptability to production environments with diverse orders and rapid product iterations, enabling quick response to market changes.

Specifications:

| SA-263 | |||

| Specifications | |||

| (Item) | SA263 | ||

| Max.machining diameter | φ26 | ||

| Max.headstock stroke | G.B. | 255mm | |

| N.G.B | 2.5D | ||

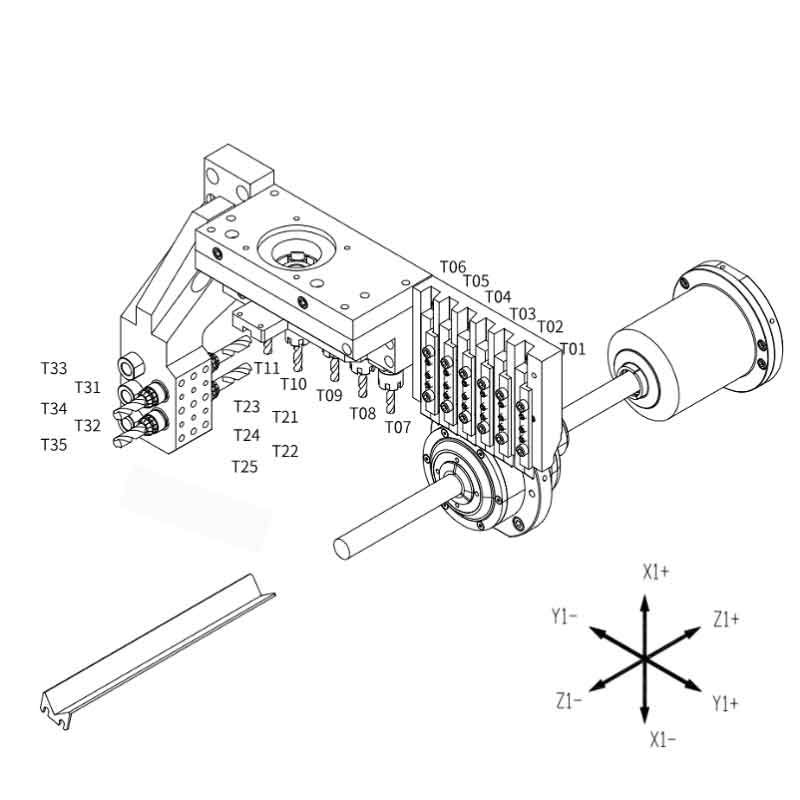

| Turning tools | Number | 6 tools | |

| Model | □12mm | ||

| Face tool holder | Number | Front-end working | 5 tools |

| Max.driling | Fixed tool axis | φ10mm | |

| Max.tapping | Fixed tool axis | M8*P1.25 | |

| Corss tool unit | Number | 5 tools | |

| Model | 5-ER16 | ||

| Max.driling | φ8mm(ER16) | ||

| Max.tapping | M6*P1.0(ER16) | ||

| Max.milling | φ10mm | ||

| Max.slotting notch | Wide:1.5,deep:4mm | ||

| speed | ER16 | 6,000rpm | |

| Drive motor | 1.0KW | ||

| Rapid traverse rate | Z1 axis | 32m/min | |

| X1 axis | 32m/min | ||

| Y1 axis | 32m/min | ||

| Main spindle speed | 10,000rpm(7,000rpmG.B.) | ||

| Main spindle indexing angle | C axis control(0.001°) | ||

| Main spindle motor | 2.2/3.7KW | ||

| Main spindle through-hole diameter | φ27mm | ||

| Coolant Capacity | 170L | ||

| Coolant motor | 0.4KW | ||

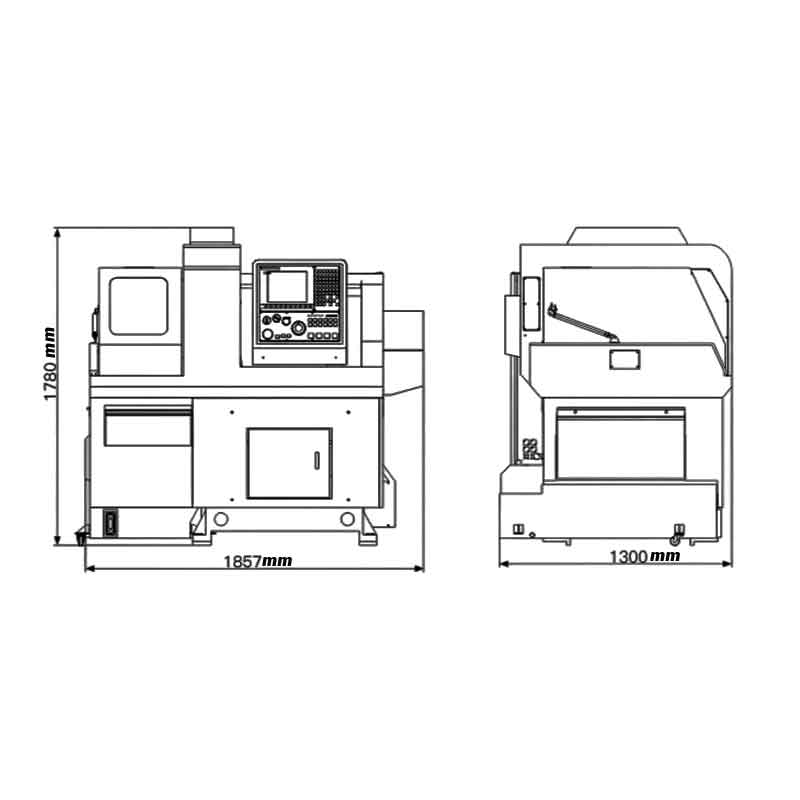

| Dimensions of machine | 1900*1300*1780mm | ||

| Weight | 2000kg | ||

Reviews

There are no reviews yet.